Summary:

The transmission project is Caltech's first design project for mechanical engineers. Each team is tasked with designing a mechanical transmission over the course of two weeks to maximize a particular speed/acceleration ratio within allowable gear ratio bounds. The competition is pretty well locked down from a motion systems standpoint, so instead my three person team decided to go overboard on our materials choice and fabrication quality.

For more detailed posts about how the transmission was designed and fabricated, see the build logs at the bottom of this page.

Design:

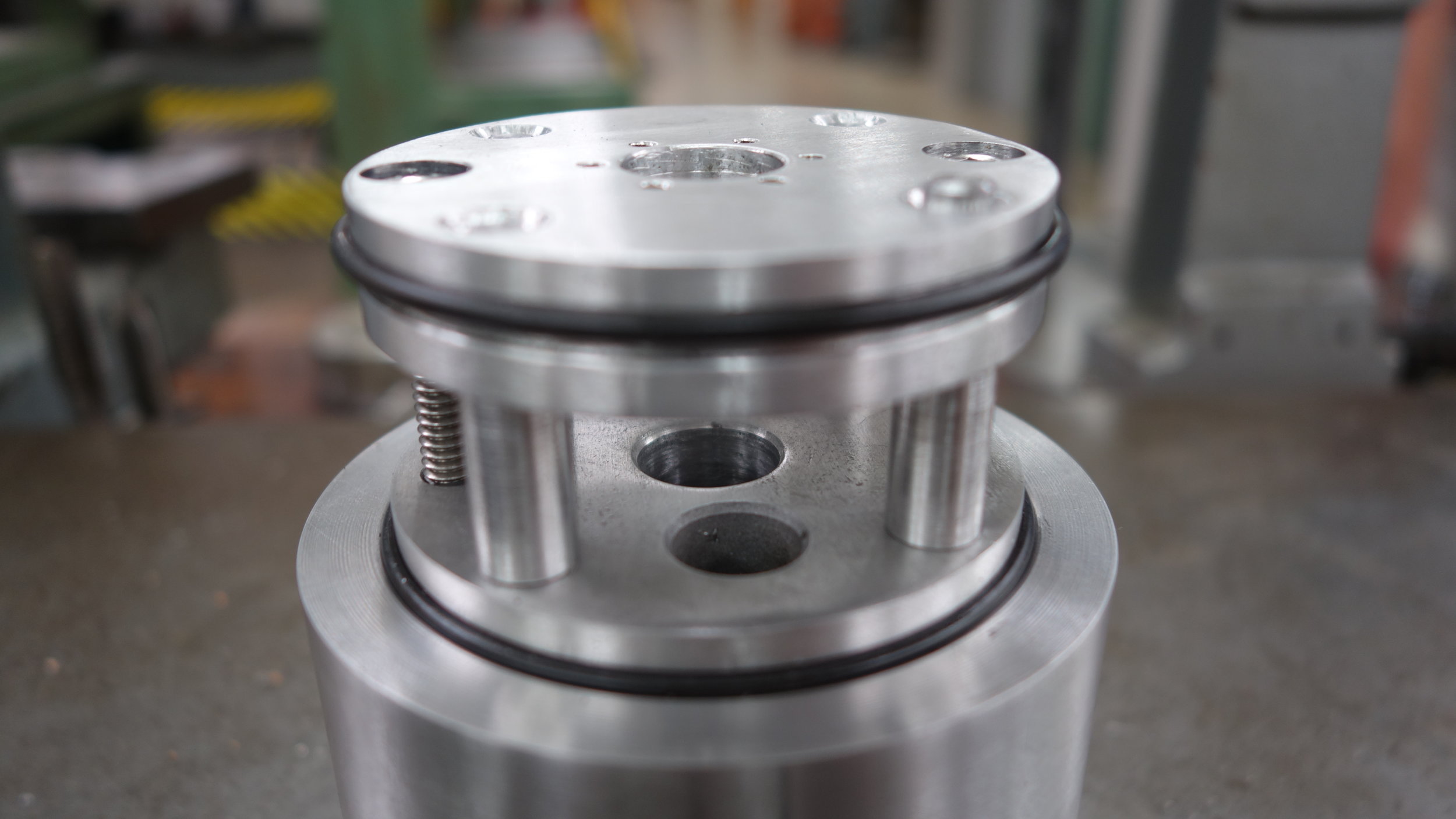

The ME14 transmission project has a longstanding, traditional, design: Two or more vertical plates of acrylic, mounted to an acrylic base, with shafts and tensioning mechanisms running between. To us, this design felt like a bit of a copout. Instead, we decided to pursue an integrated transmission module encased in a cylindrical aluminum housing. This gave us a design that, while a little big, could actually be installed in a mechanical system without risk of contamination or damage.

Having an all-metal transmission also let us solve the wear issue. Traditionally, ME14 transmissions run dry. This is good for competition day performance, but means that they only have a few hundred hours of operating time. Instead, we designed our transmission to be entirely filled with spindle oil and then run in. That cost us some top-end performance, but massively decreased gear wear, and is perfectly in line with the "reliability first, quality first" design ethos we have tried to pursue as a team.

Fabrication:

The majority of our parts were made using a lathe and rotary table / mill. Generally we broke each of the circular parts into two separate machining sessions. First we would prep the stock. This entailed starting from scrap, and then turning the final dimensions. Once the blank had been prepared we would drill/ream and tap any holes or pockets in the parts.

The only major exceptions to this recipe were the spacers (which we drilled on the lathe) and the stand plates, which were fabricated entirely on the mill/rotary table.

The Team:

I was honored and thrilled to work on this project with two other students (below). Both of them put in a massive amount of time, and were delightful and educational to work with. I look forward to doing more projects with both of them moving forward.

Alexander Reeves.