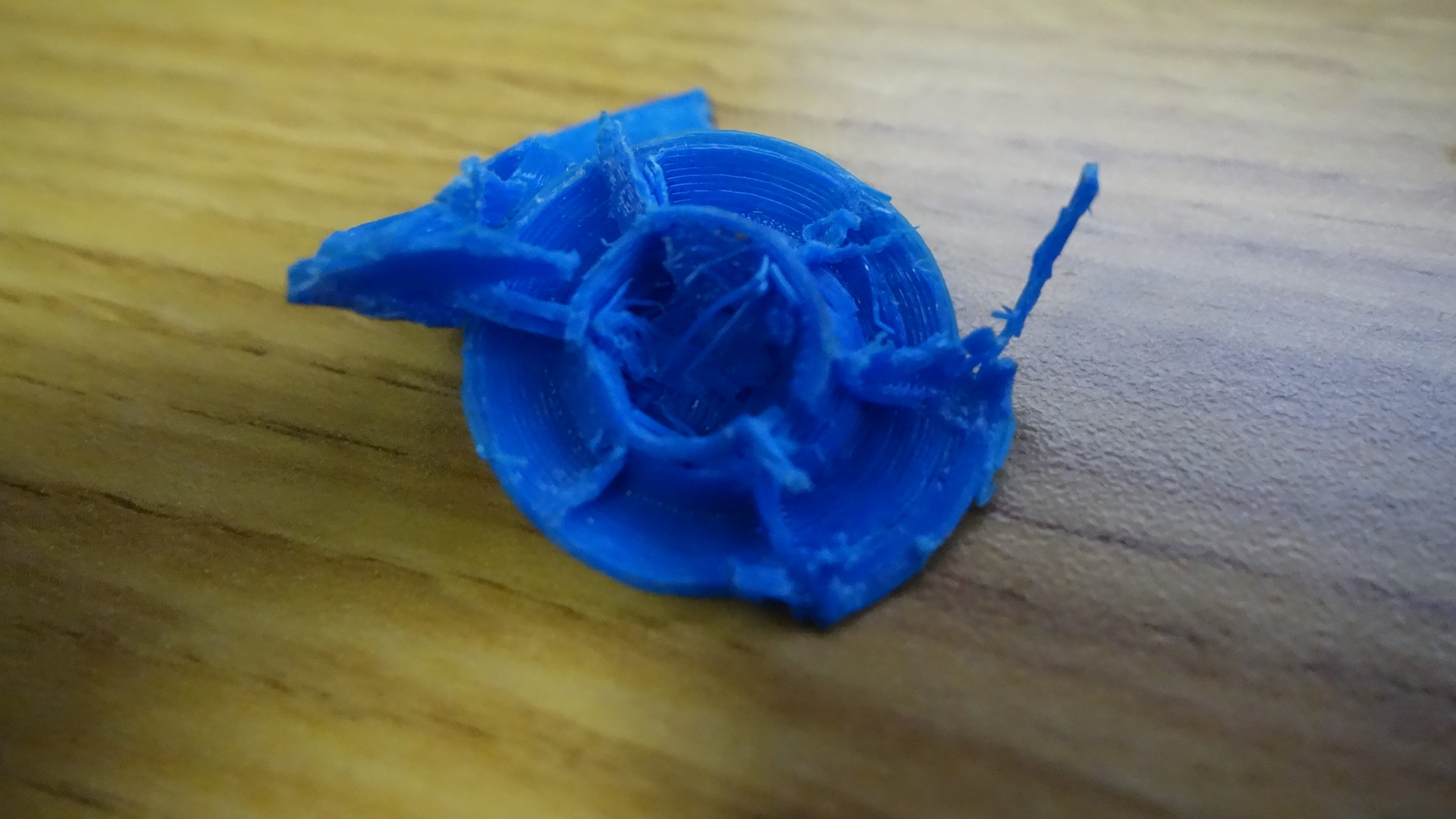

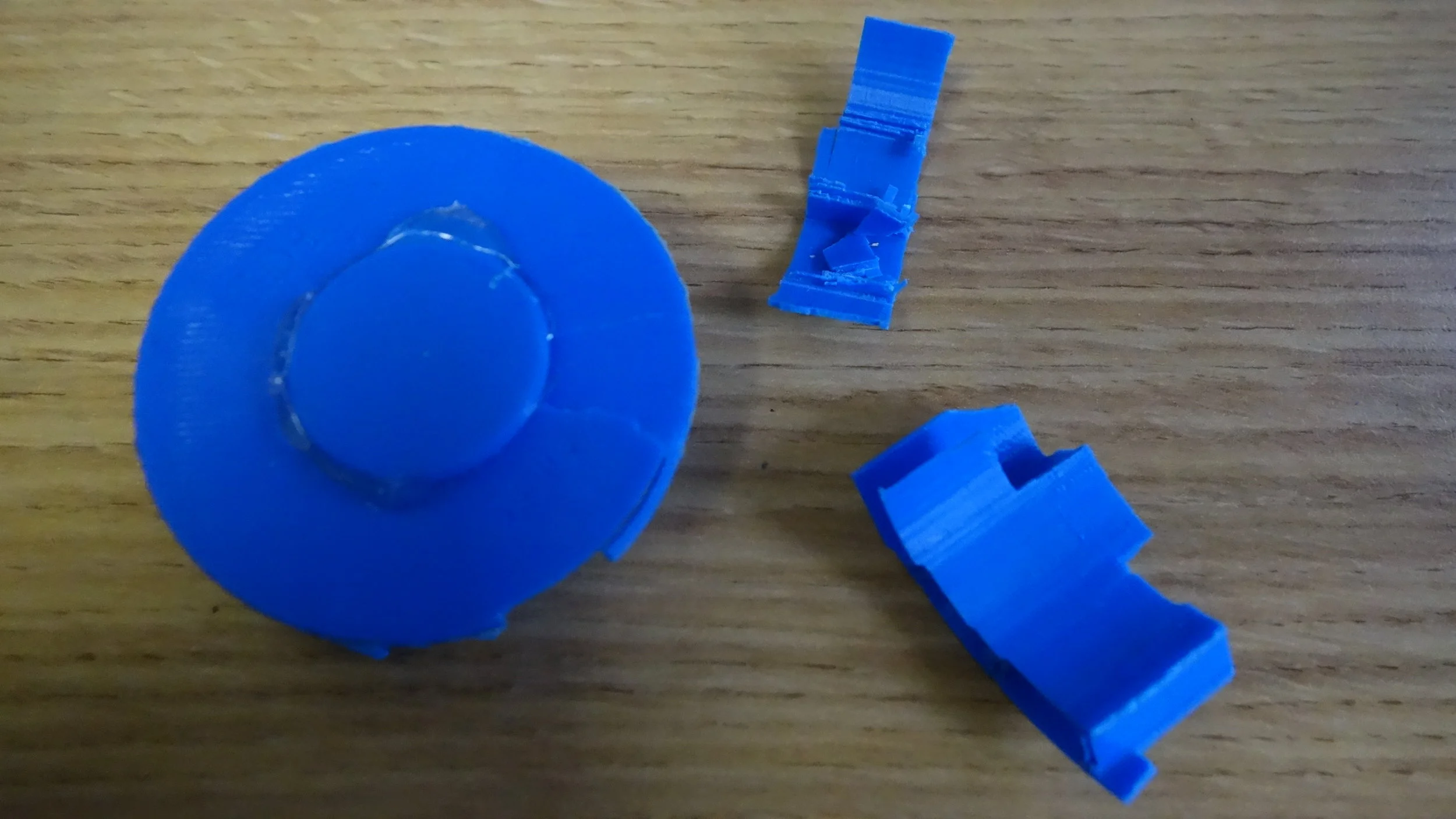

The cannon firing a pineapple during the same series of tests… It mostly just exploded.

Photo Credit: Brian Cruz

Goal:

Blacker house has a potato cannon (pictured right) which we roll out during rotation, and then sporadically throughout the year. Naturally, we have tried firing many things out of the cannon which are not strictly speaking potatoes, generally with entertaining results. However, it has historically been somewhat difficult to launch powdery or liquid materials without making a gigantic mess inside the cannon. This project aimed to change that.

To be a bit more specific, a good potato cannon round must:

Fit inside the cannon.

Survive launch.

Carry a reasonable payload.

Break up into small enough pieces not to pose a hazard to viewers.

Be easy and inexpensive to fabricate.

Fabrication Documents: CADs

Experiments:

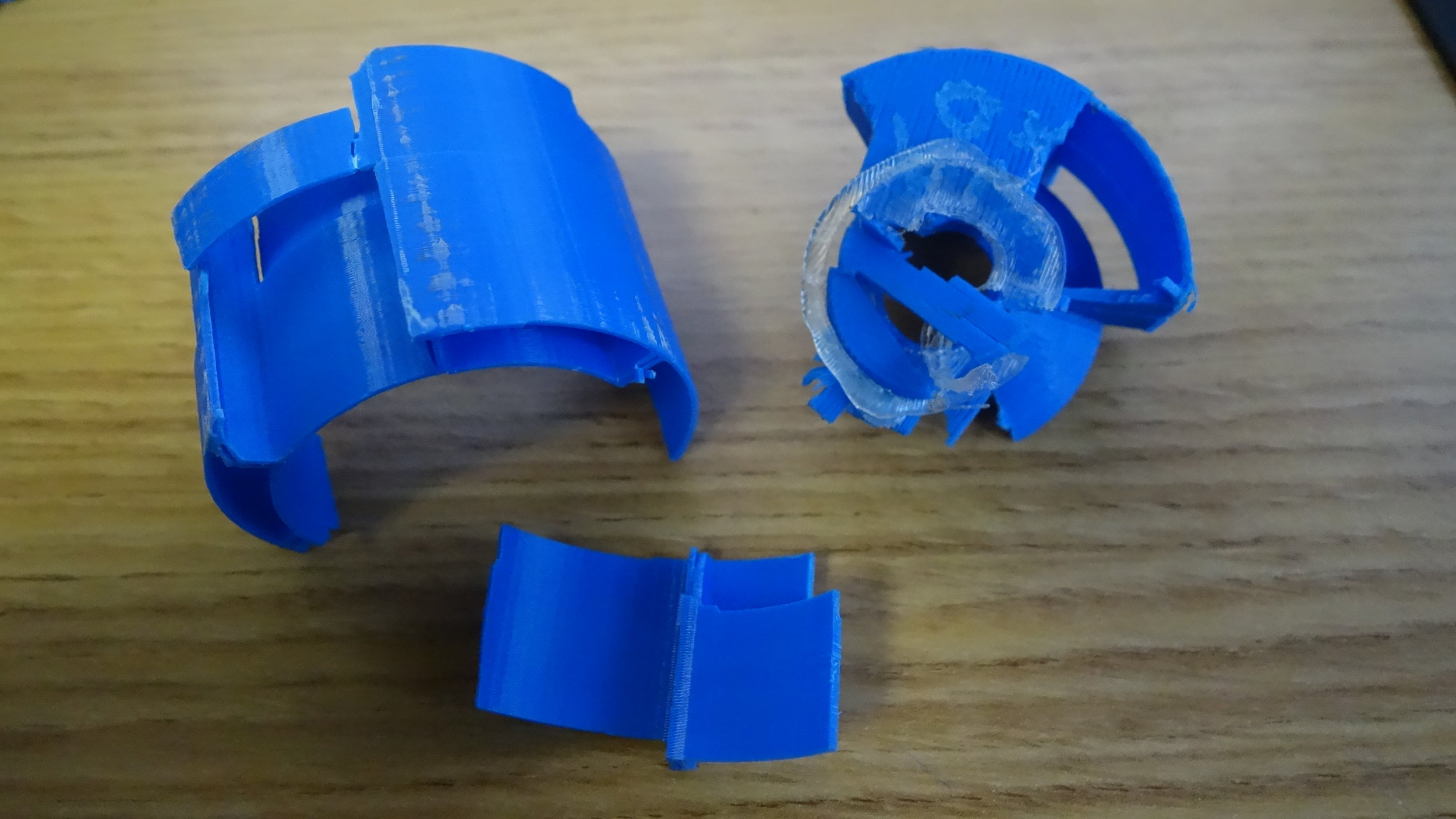

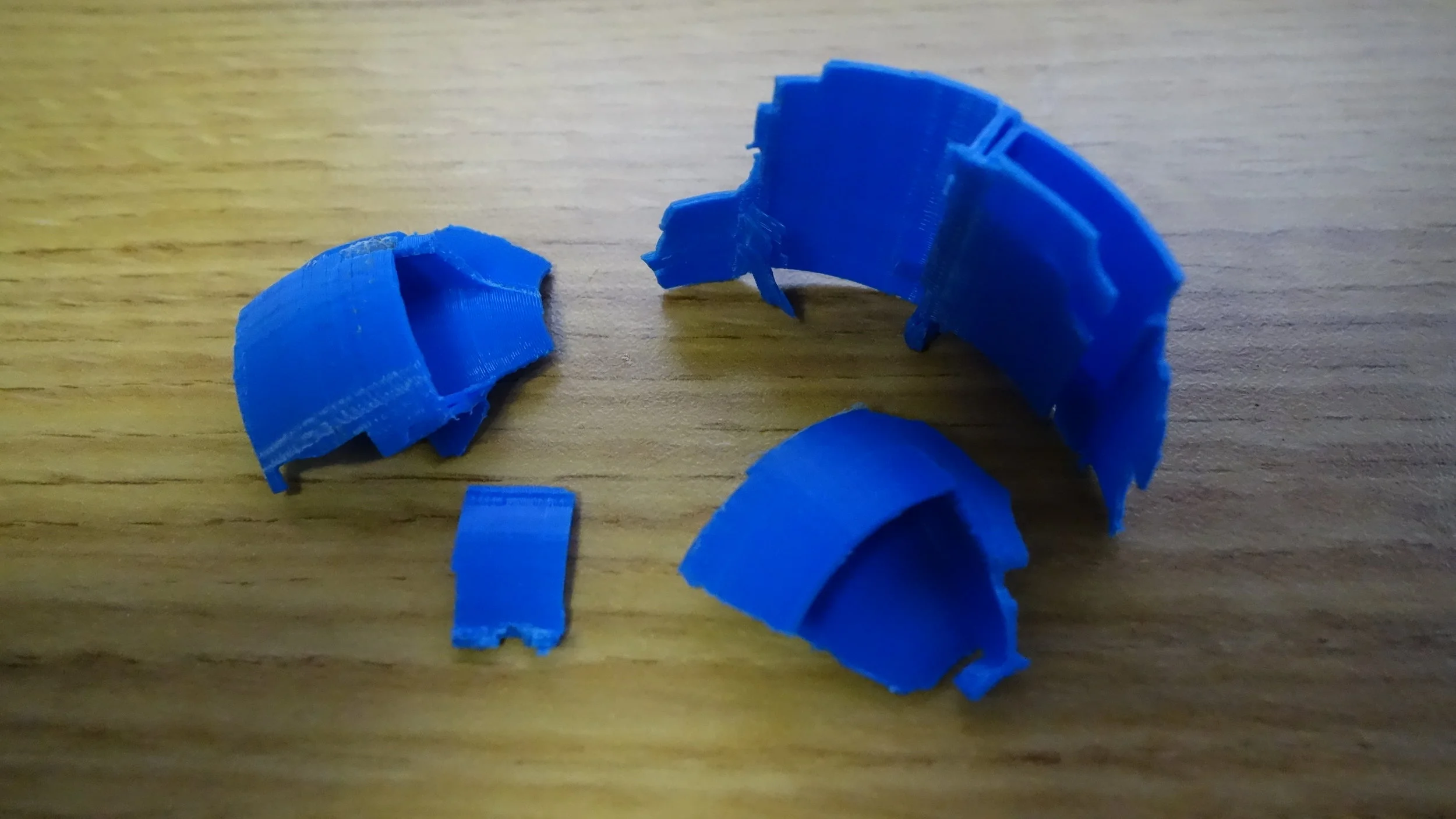

Process: The goal of this project was to generate a good design for a water round for the cannon by varying the parameters of our model. To that end, we printed 30 rounds with varying designs (see below), and fired them at a plywood target. To get a sense for when and how rounds failed we collected the fragments after each firing and, when needed, recorded video of the round being fired. All of the rounds used for data collection were filled with water and caped with hot-glue and the standard cap disks. However, we did also fire rounds containing dry ice, LN2 and ice to good effect.

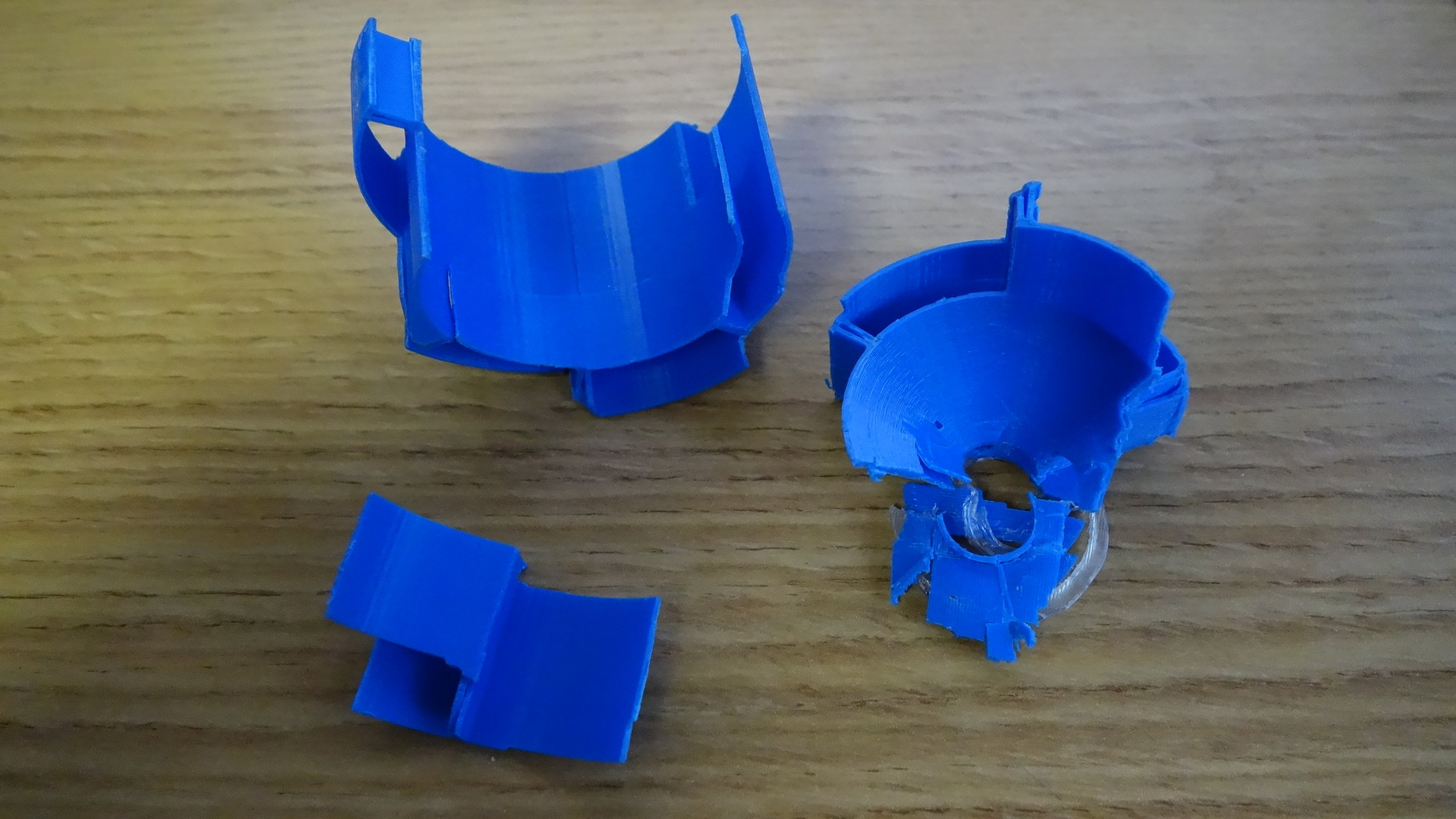

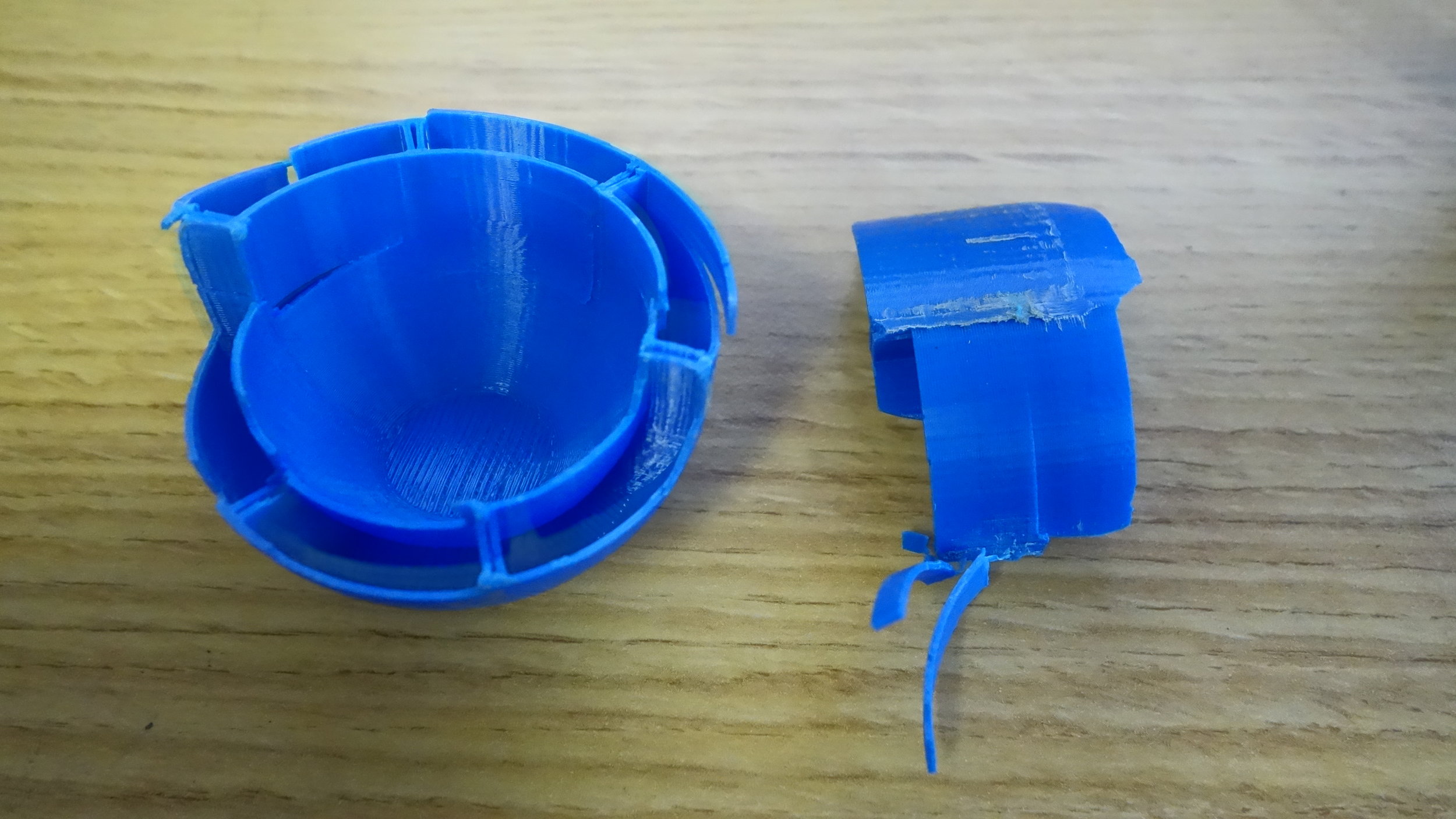

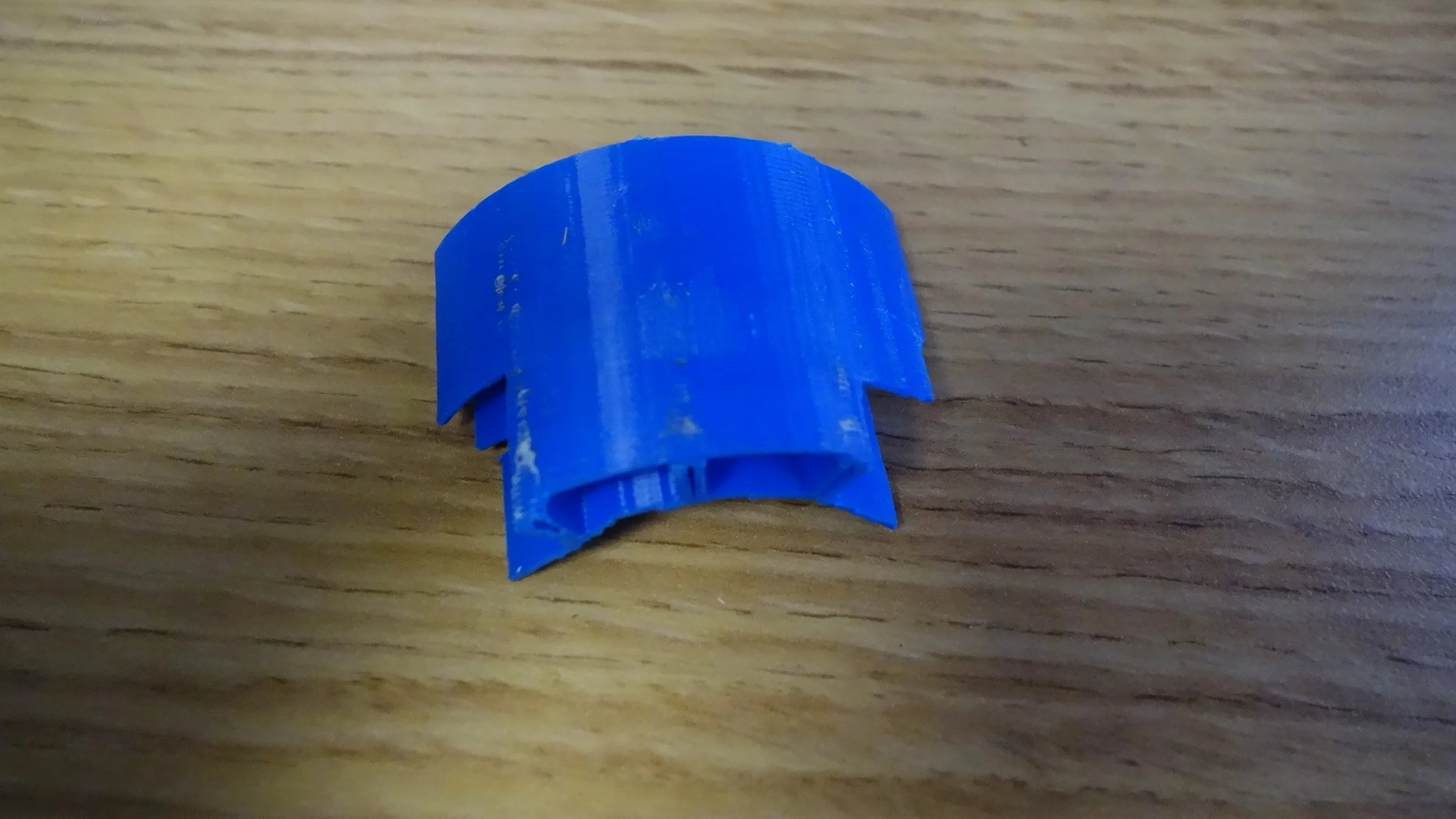

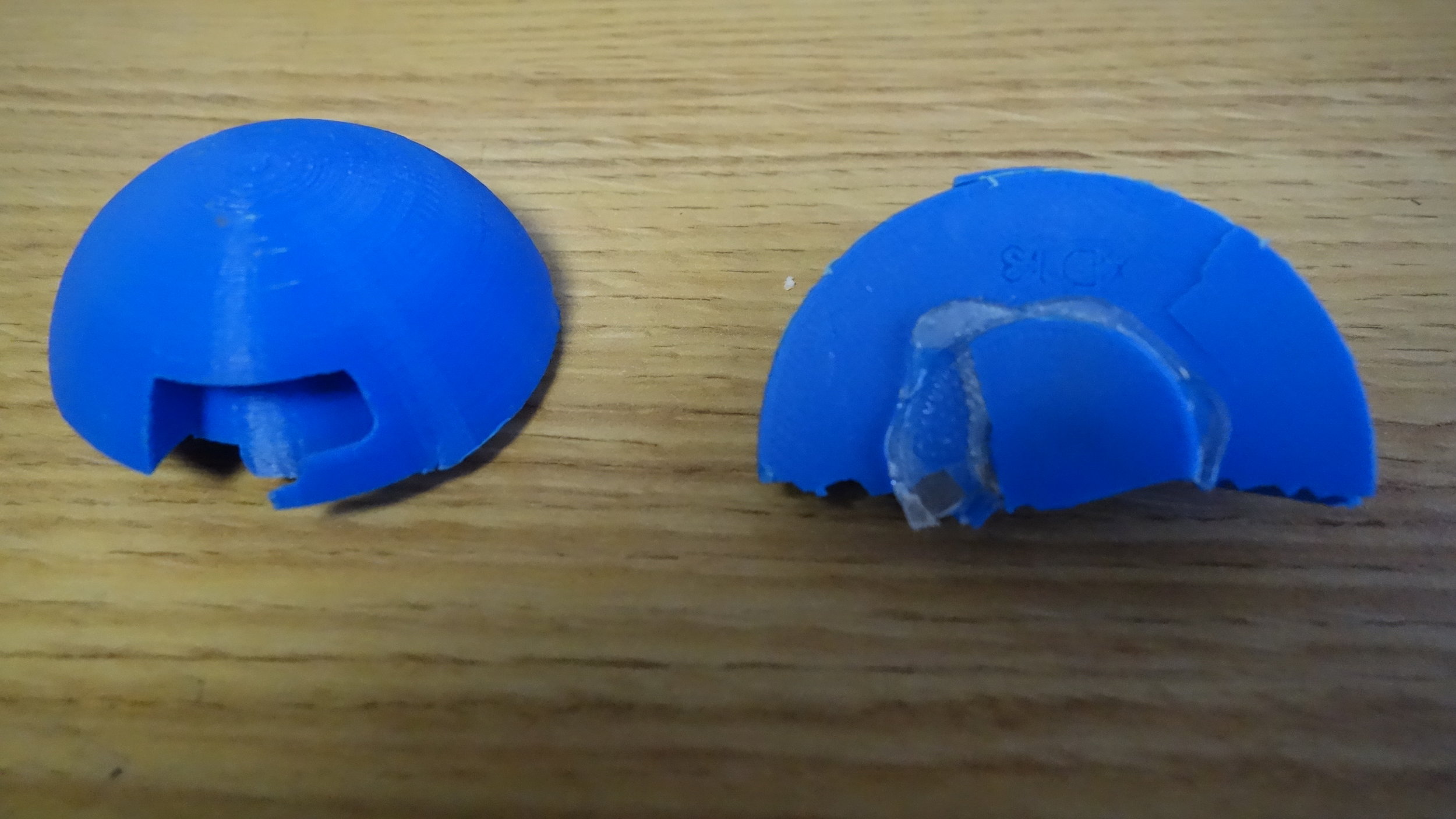

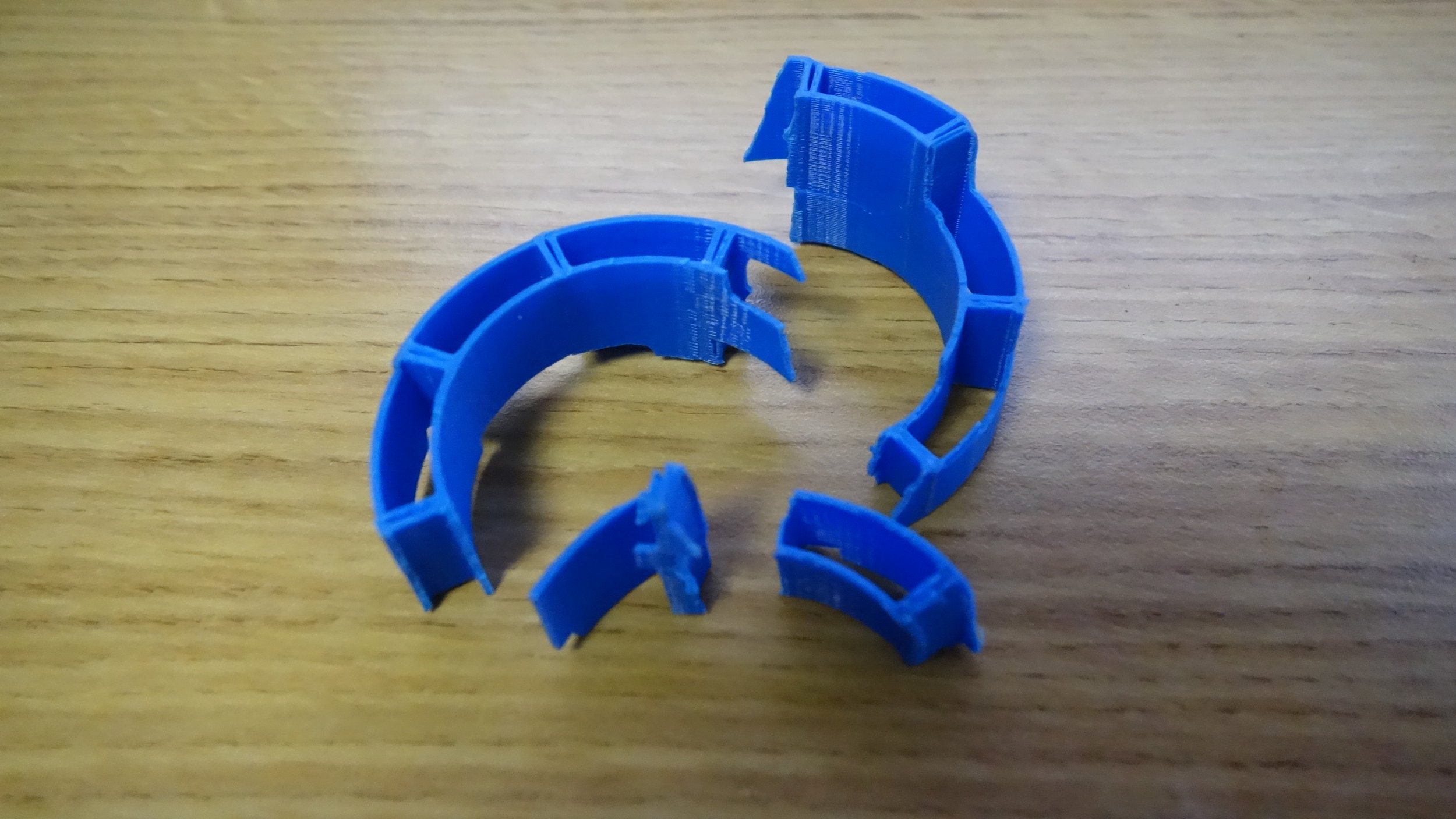

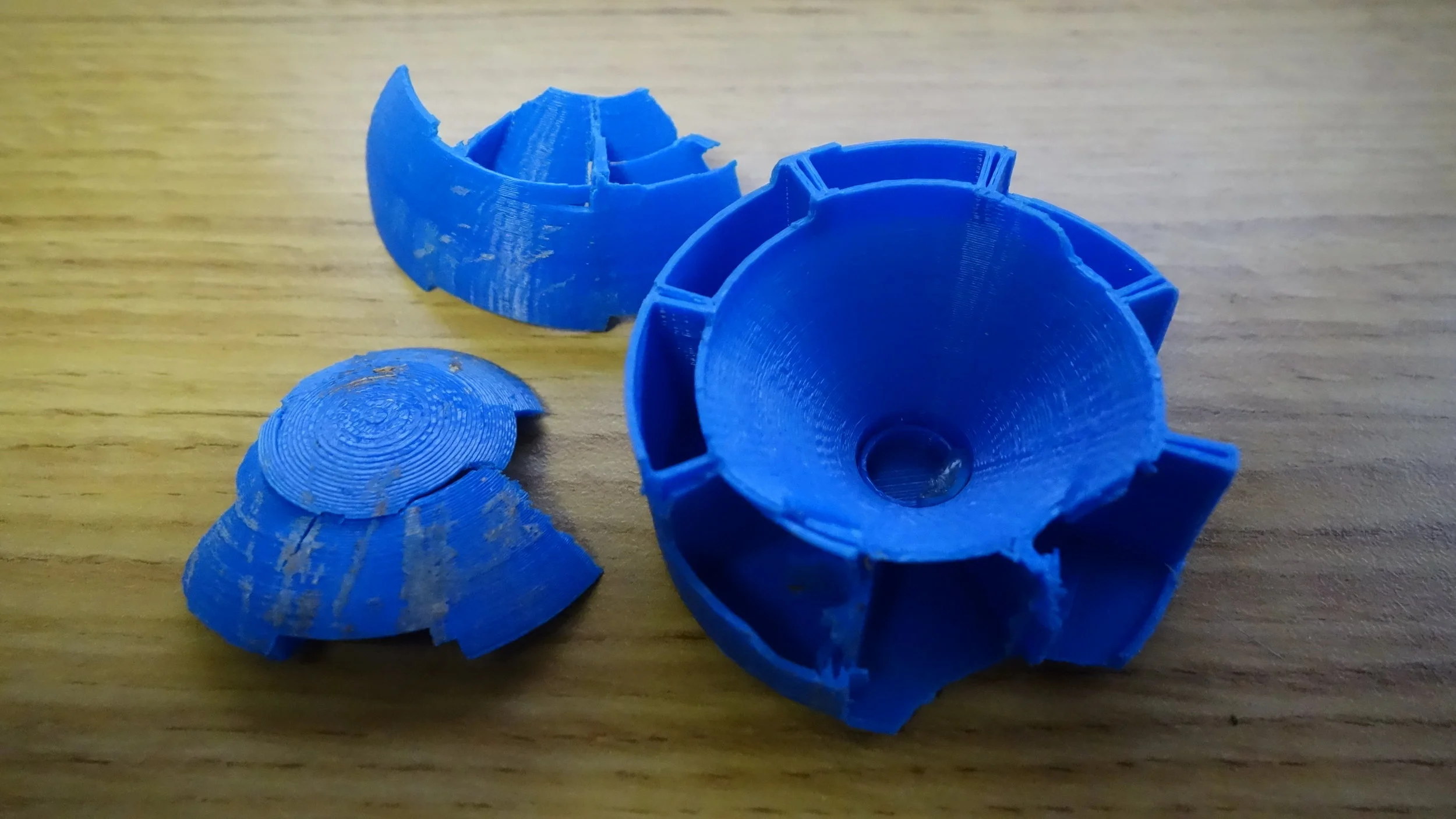

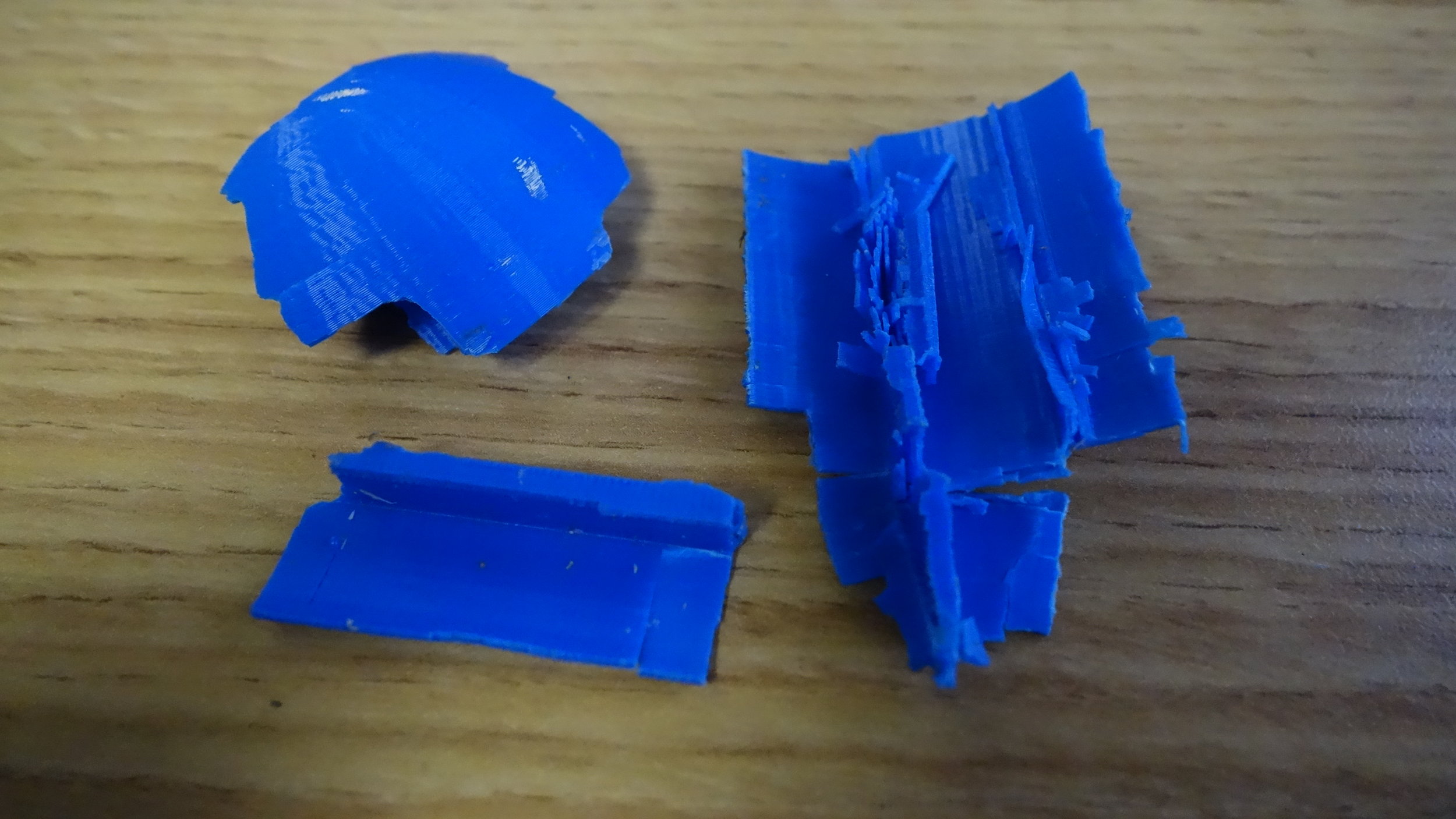

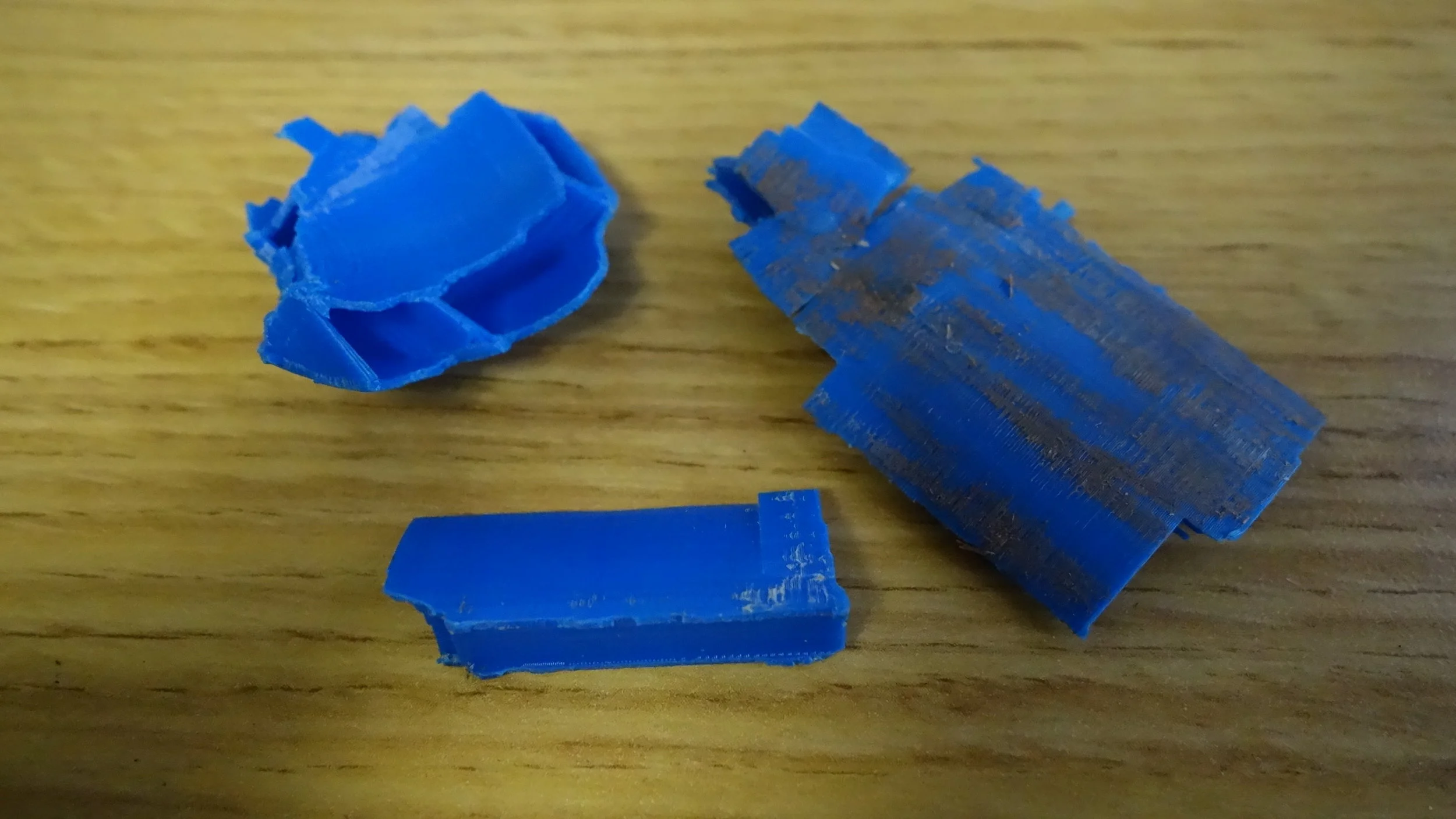

Design: In an effort to maximize our strength per weight, we settled on a double-walled design, with an outer shell held onto a watertight inner shell using ribs. For the most part, the rounds were entirely wall, and thus had no infill. However, most of our rounds did have a “tip” section at the tip of the round printed at a higher infill to provide weight and reduce tumbling.

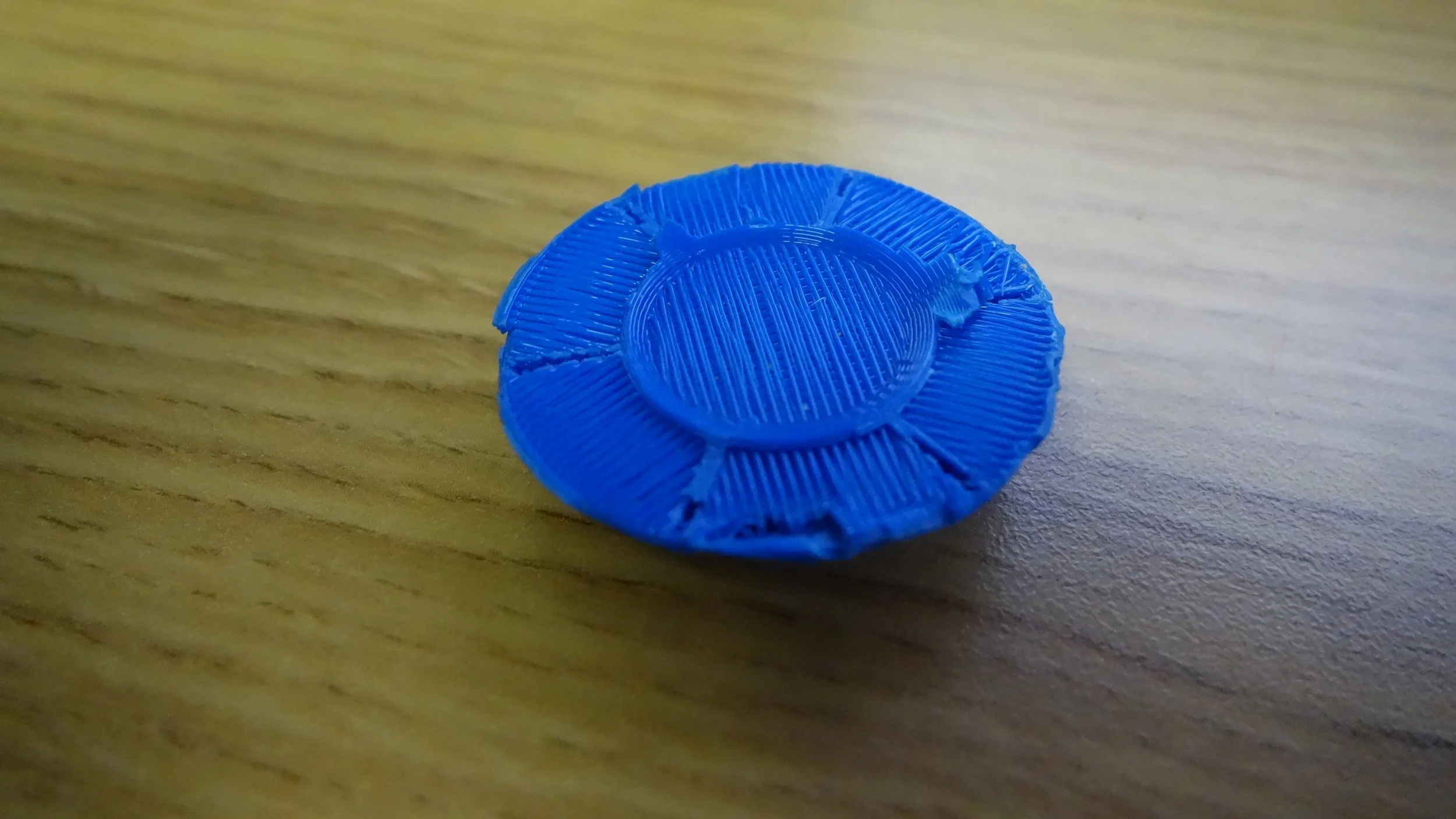

To cap the rounds, we printed a number of small disks with locating rings. These fit into the hole on the back of the rocket and were hot-glued on before firing. We found this to work quite well, with most caps apparently remaining intact as long as the rockets did.

Fabrication: Since we wanted relatively complex shapes, and relatively low fabrication costs, so 3D printing made perfect sense. All of our prints for this project were made on Nathan’s slightly modified Monoprice Ultimate. The rounds themselves were printed in “series” (below) which internally share a design. The caps were common between all designs, and were printed in batches as needed.

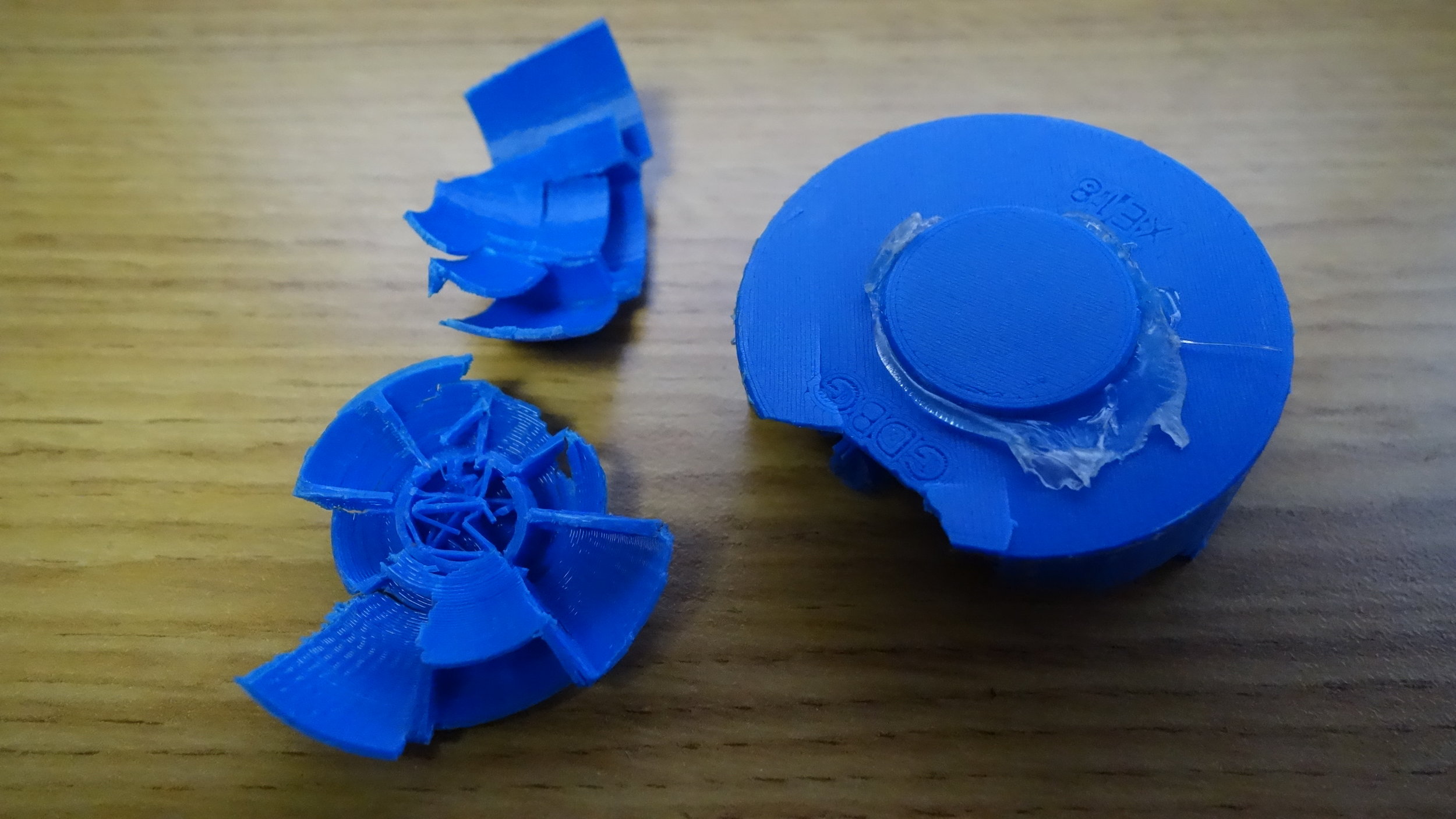

Top of the XD series, right below the solid cap.

Bottom of the XD serries. You can see the added bottom chamfer.

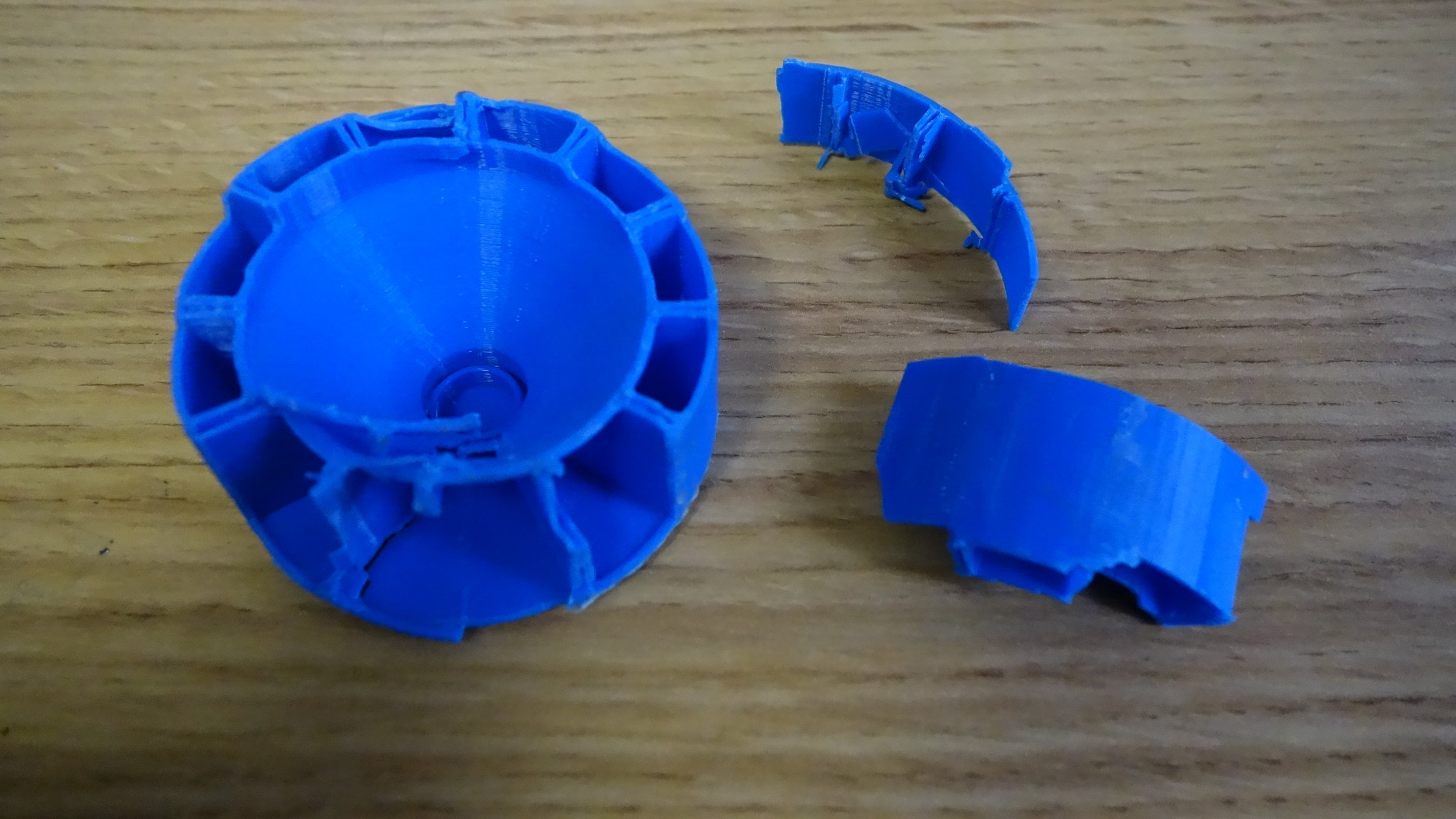

XB series: .8mm (2 layer) outer wall with 6 full length longitudinal ribs connecting the inner and outer walls. Top cap printed at 85% infill. Consistently survived for impact. Retired after a cap segment flew 50’ to strike a second story window. (Why the courtyard has safety glasses)

XC series: Same fundamental design as the F series, cap infill reduced from 85% to 10%. Round failed in the air well before reaching the target.

XD series: Reduced cap height to the very top of the part, added chamfer to bottom of inner chamber. Cap infill set to 15%. Most rounds failed on impact, though we believe XD13 failed mid-flight. We nave not identified what caused that failure.

XE series: Increased cap infill to 25% and increased the number of ribs from 6 to 8. Consistently survived to impact.

XF series: Increased the number of ribs from 8 to 12. Based on the denting and landing patterns we believe these failed on impact. Performance seems improved over the XE series.

XG/XH series: G had the same geometry as B/C, with a 50% cap infill and bottom fillet. XH had 65% cap infill. No performance difference. Video evidence suggests survival to impact. However, no denting could be identified on the recovered caps.