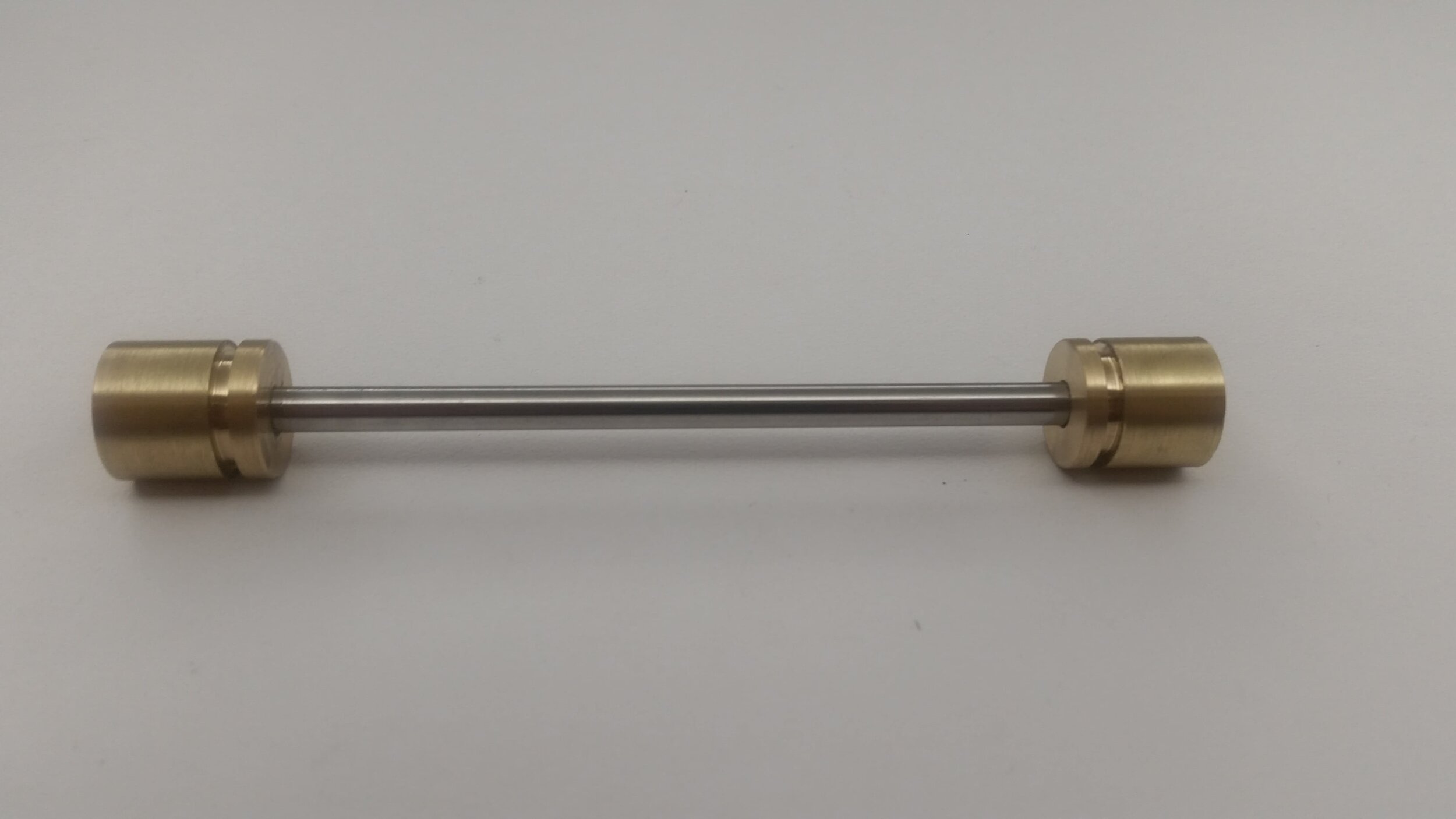

This is a stamping and branding kit made for a friend. The two shallow stamps, and short stem are meant for use stamping sealing wax, while the deep stamp and long extender are intended for use branding wood. Included in the gift are two partially finished heads, which will be machined with new designs as requested.

The heads and handle are made out of free-machining brass, and the two stems were cut out of 303 stainless steel rod. All of the parts fit in a 3D printed case, which is held together with an elastic latch.

Fabrication:

The heads, handle, and stems were turned on the lathe, and then the heads were engraved on our Haas TM1. The stems and handle were both cut to dimension on the lathe, while the heads were parted long and then finished to final dimension on the CNC. All of the threads are 1/4-20, and were cut with a tap or die.

The grooves were all cut with the student shop’s 1/8in parting tool, and The engraving was done with 1/32 and 1/16 ballnose endmills. The parts were then finished with 1500 grit sandpaper and lightly buffed.

Files: [CAM/CAD]

Notes for next time:

Consider finger grooves for the head holes.

The screw/band latch works pretty well, but it would look better with the screws on the ends.

It helps to slightly file down the threads after they have been cut.

303 should be threadcut with a sharp die (if available) and without backtracking if possible.

Figuring around 30 minutes per part, plus CNC will get you in the right general ballpark for planning purposes.

Finished Project:

Machining Photos:

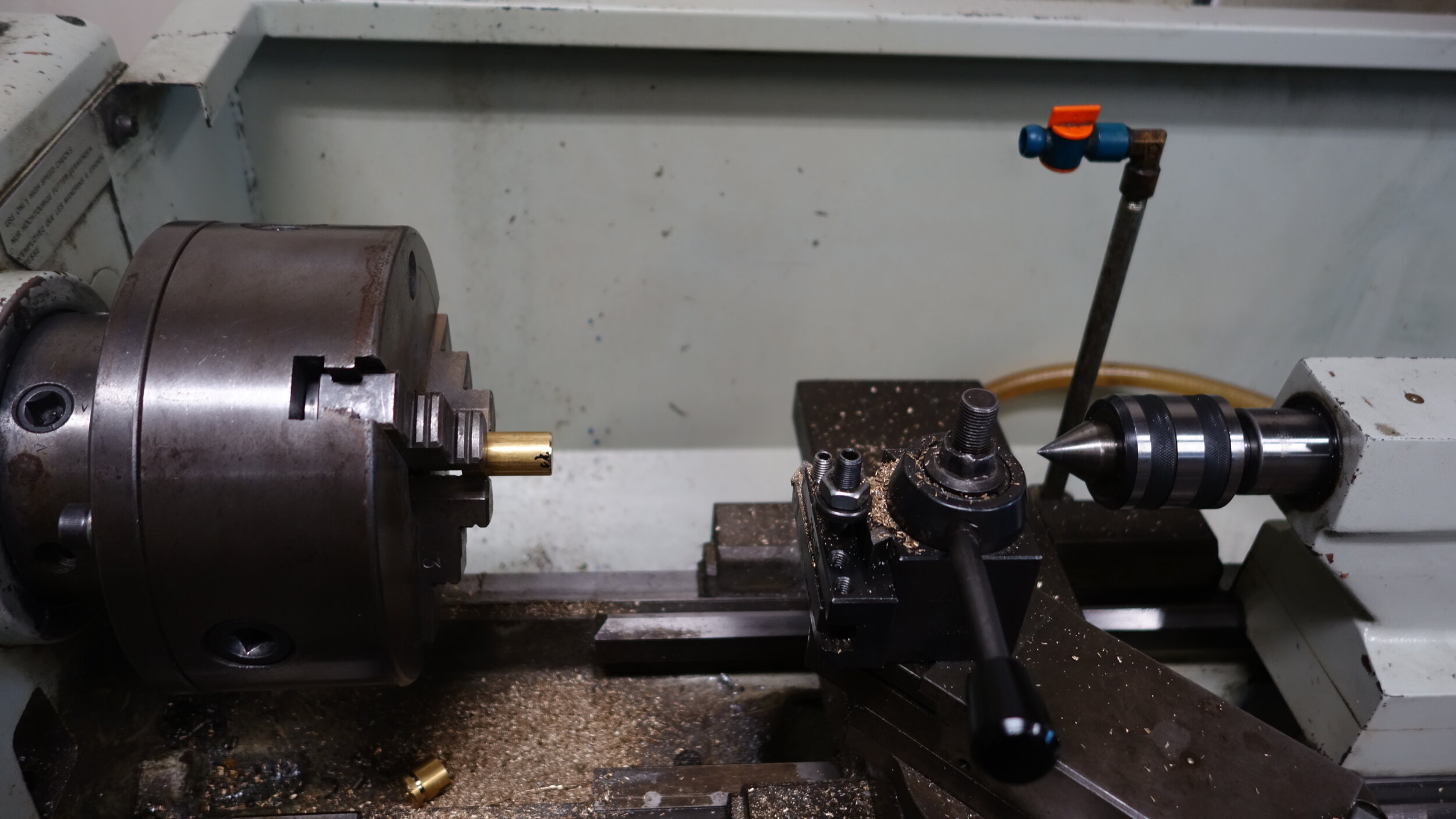

My old tapping setup. Honestly it worked fine, but moving the tailstock in was time consuming, and introduced a bit of wobble at times.

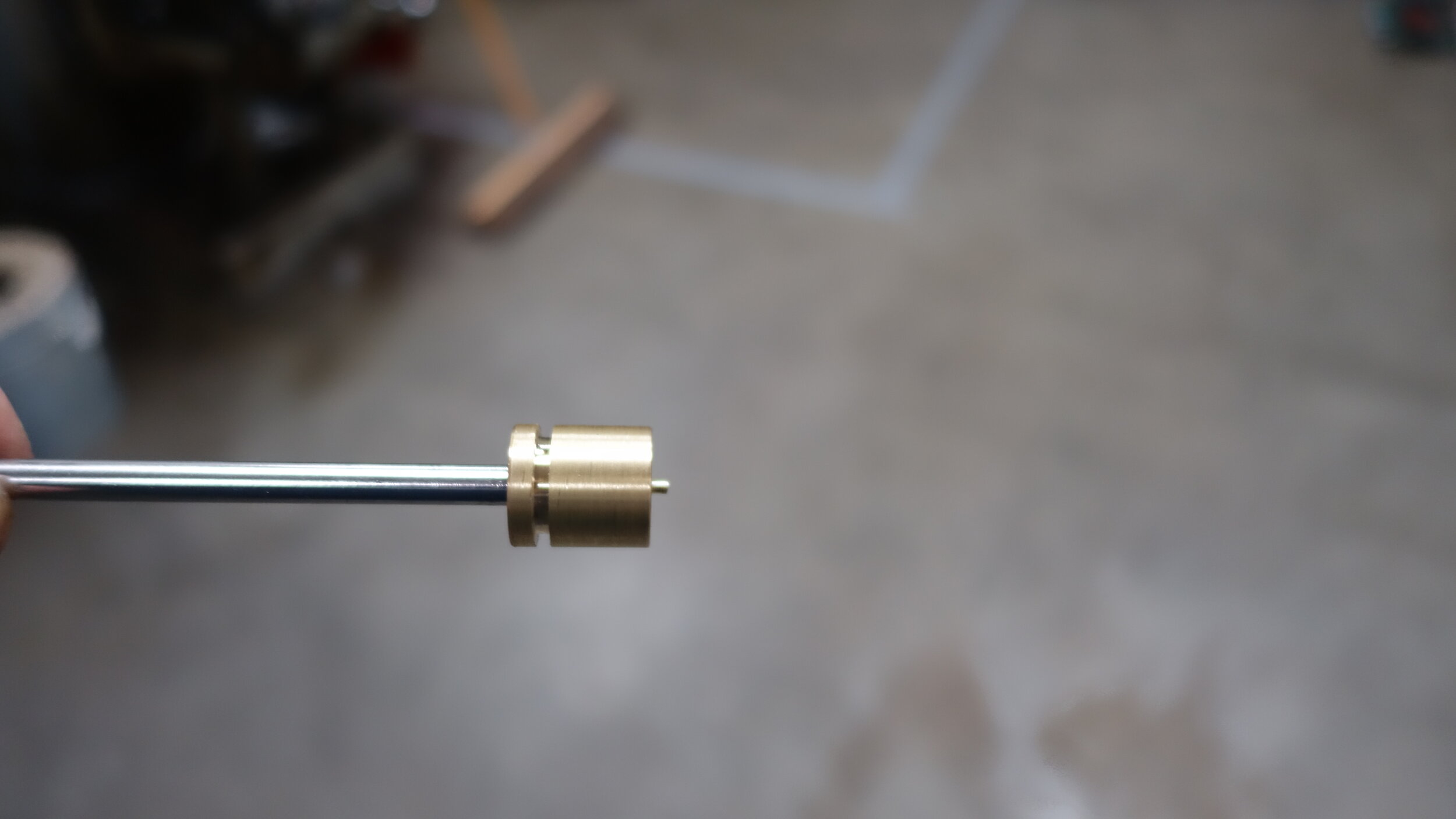

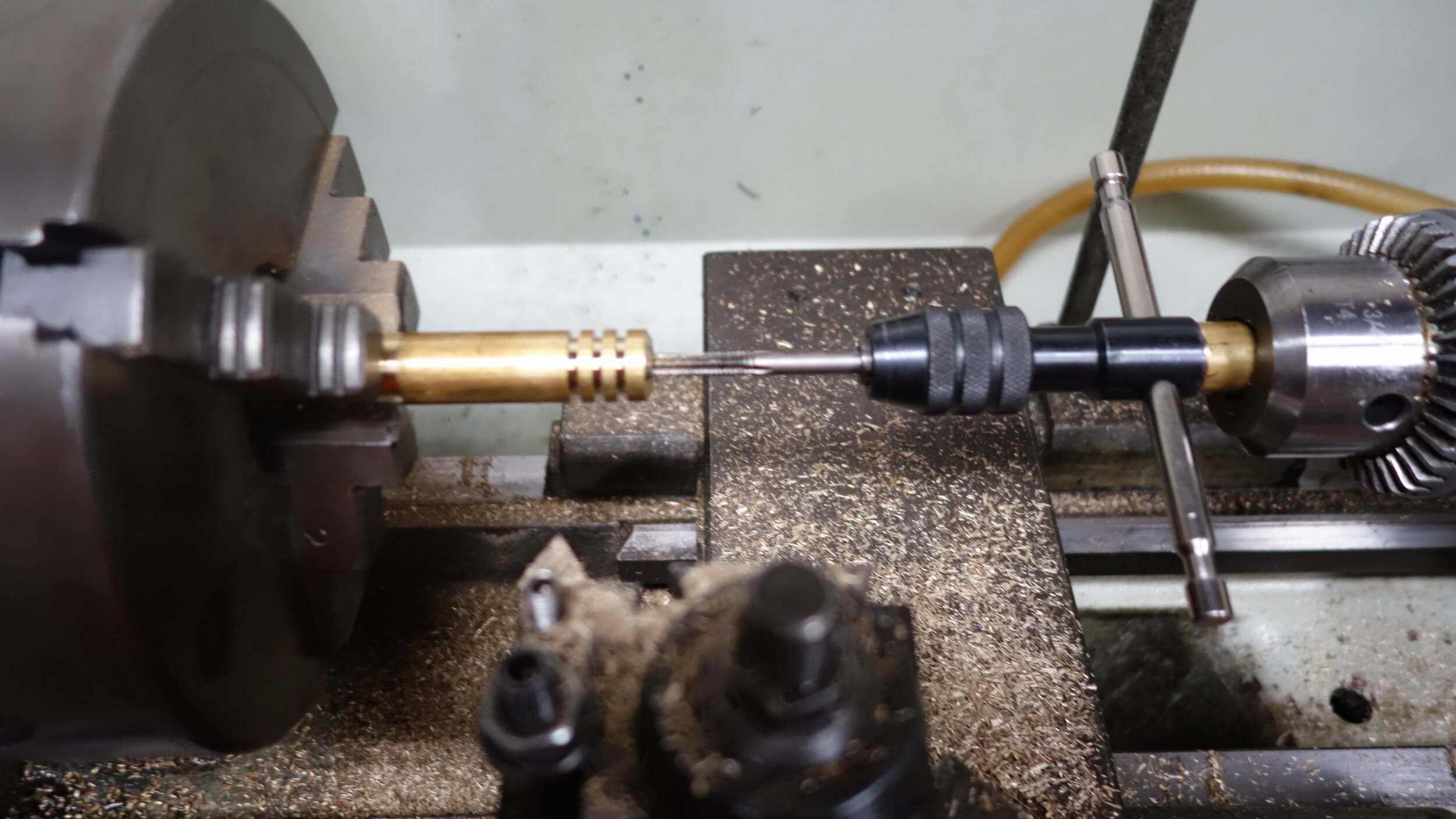

My new tapping setup. A brass bushing holds the back of the tap wrench straight, while providing about half an inch of travel before the tailstock needs to be advanced.

1500 grit Rhynowet Redline sandpaper. A bit overkill for this purpose, but works well.

Turns out the stems also make pretty good arbors so long as you don’t take deep cuts.

Mouse Barbells