Summary:

An LED lighting system for the living room of our new apartment! So far we are about a week in and I’m loving the little bit of extra flair, plus it makes a pretty great night light.

I’ve put up similar systems in a few places, but this is the first setup (excepting the original) that is a complete display with 4 sides, permanent wiring, and support for all the existing patterns. Now that it’s up and running I plan to start writing patterns again, and maybe even roll out a V3 controller if the extra memory / sensors ends up being necessary. I have temporarily scrapped the multi-controller version of the firmware as too complicated for not enough added flexibility.

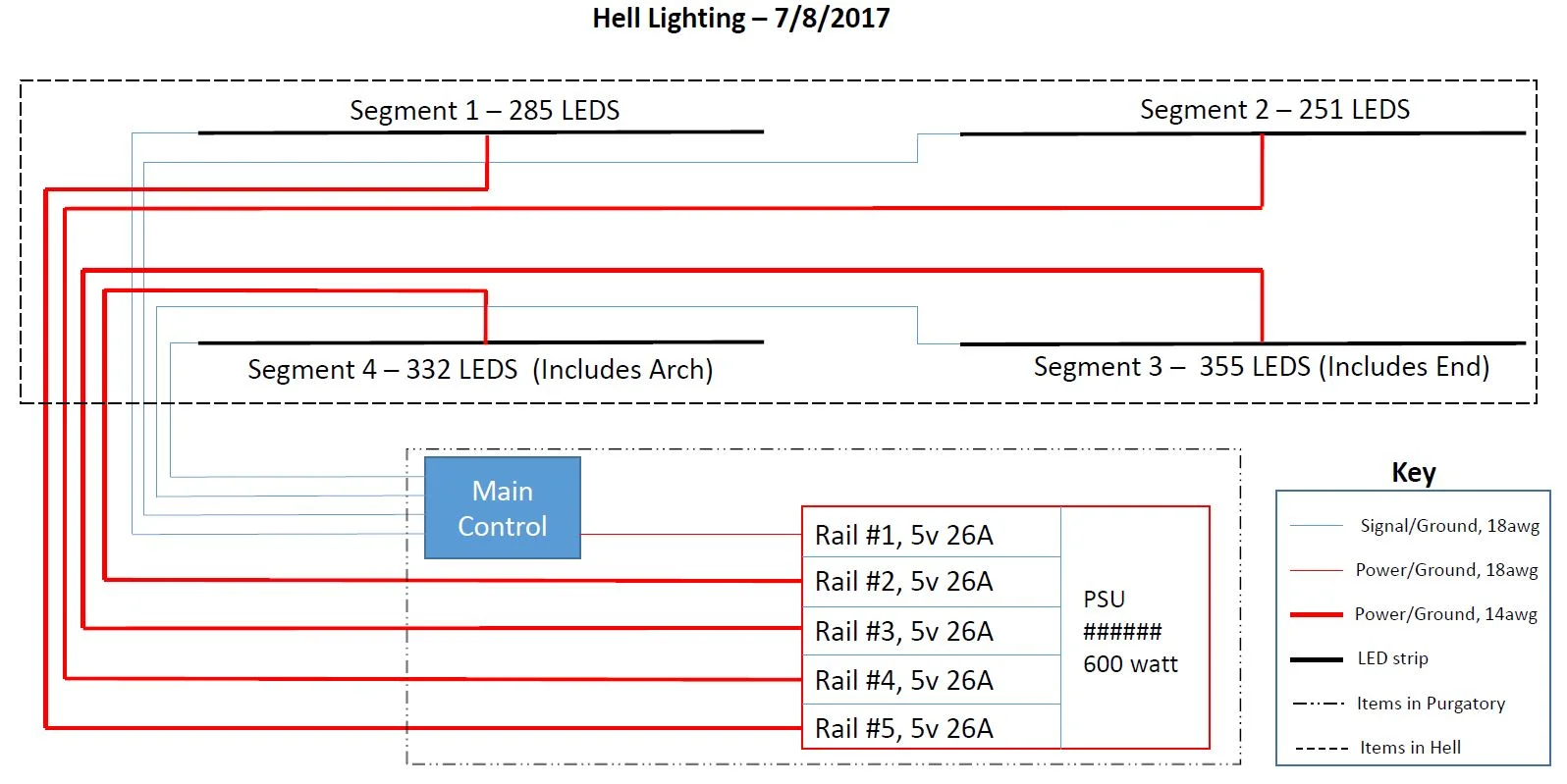

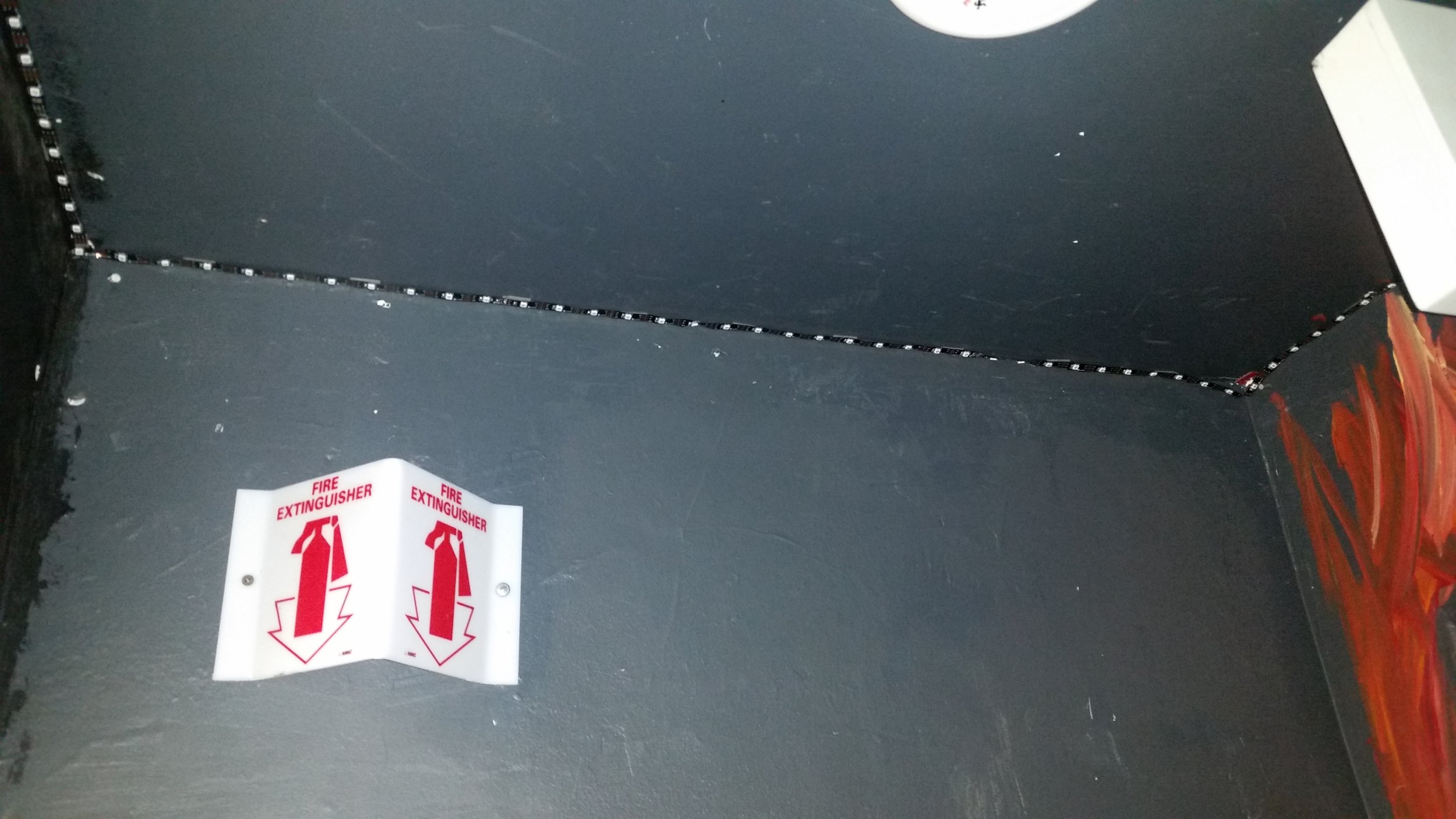

Our living room is a much smaller space than the Alley of Hell at Caltech, but with double-density LED strips still have 967 LEDs, just a hair under 80% as many as the original system. I like the higher density (60 leds/m instead of 30leds/m), and I particularly like how we were able to run the strip inside the molding. It gives the install a softer, more organic, look and the effect is definitely something I’d aim to duplicate in future systems.

Software Tweaks / Layout:

Unlike the original, this system uses two strips instead of four, and both strips originate in the corner we want to make the top right. To accommodate this we zero’d strips 2 and 3 in the config files, and updated the lengths to match the installed LEDs. We also updated the mappings for the two walls and two end caps to match the new room. I find that the race pattern is great for that process because it so uniquely identifies the four regions.

New Patterns:

We have one new pattern associated with this install “white”, which just displays white across the whole strip. The potentiometer controls the brightness, and it makes a nice night-light for folks who are sleeping over. It also doubles as our “off” pattern when the pot is turned all the way down.

A downside of using two end-powered LED segments (as opposed to 4) is that we see some color aberration towards the end of the strips for bright patterns. Since the strips are the same length the color shift is symmetrical at the interface point (which hides it a bit), but it does mean we have to be careful about patterns like “white” or “rule 101” that generate lots of all-white LEDs. The sparser patterns like “purple”, “trains”, or “morise code” are not impacted.