Story:

Every year for pre-frosh weekend* my house, Blacker, holds an event called "deconstruction" during which we destructively disassemble a pair of unusable bad pianos. The pre-frosh are given a selection of sledge hammers and crowbars, while the current students are restricted to whatever we can find lying around the courtyard and on our persons (this is less of a handicap than it would seem, "pulies and a tree" both fall into that category). I was originally planning to use my machinist's hammer, since I have been carrying it around campus as part of that project. However, I was worried that it might not hold up all that well to prolonged use against cast iron. This then is a slight iteration on that design explicitly intended for use smashing pianos.

Hammer:

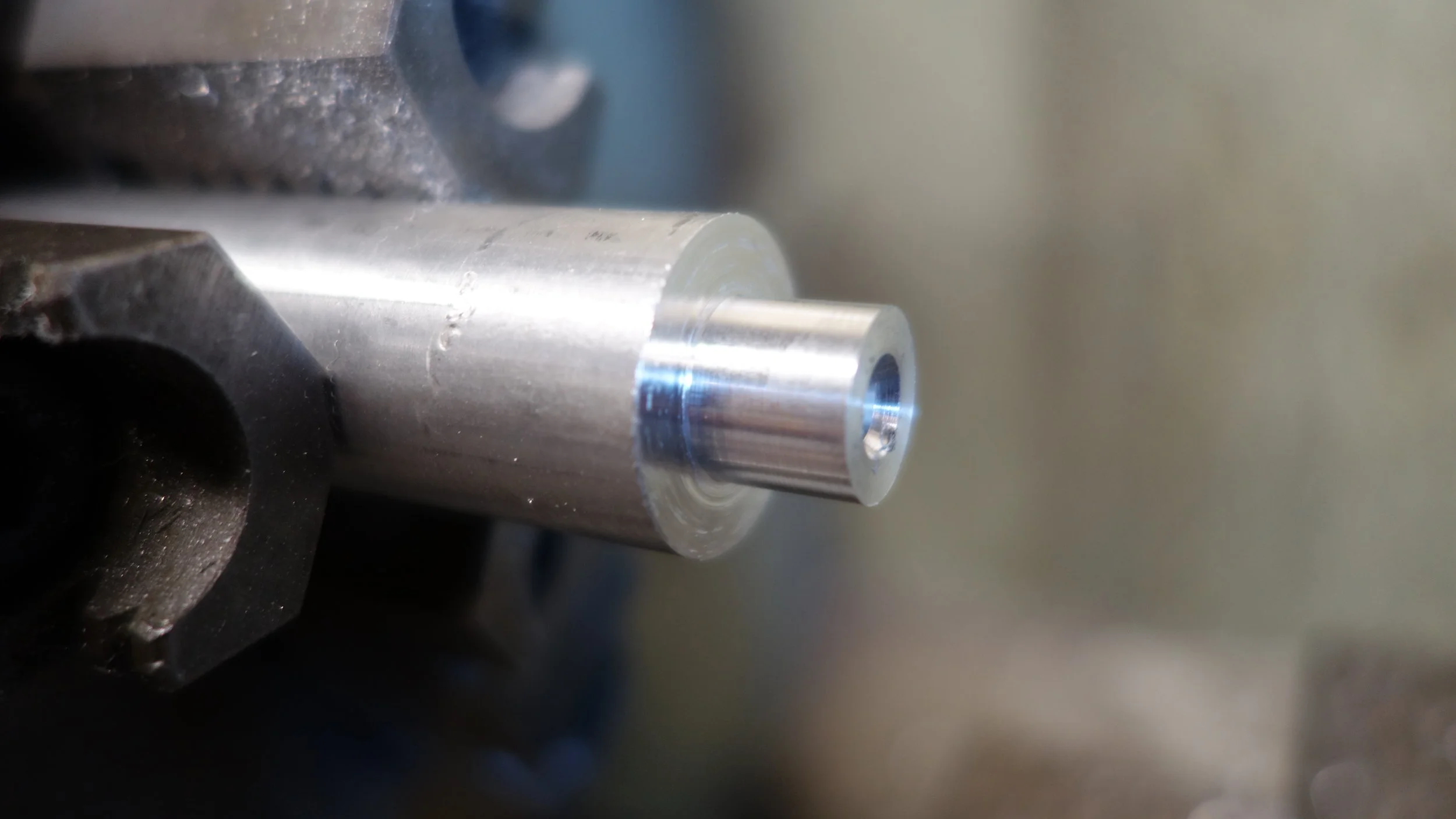

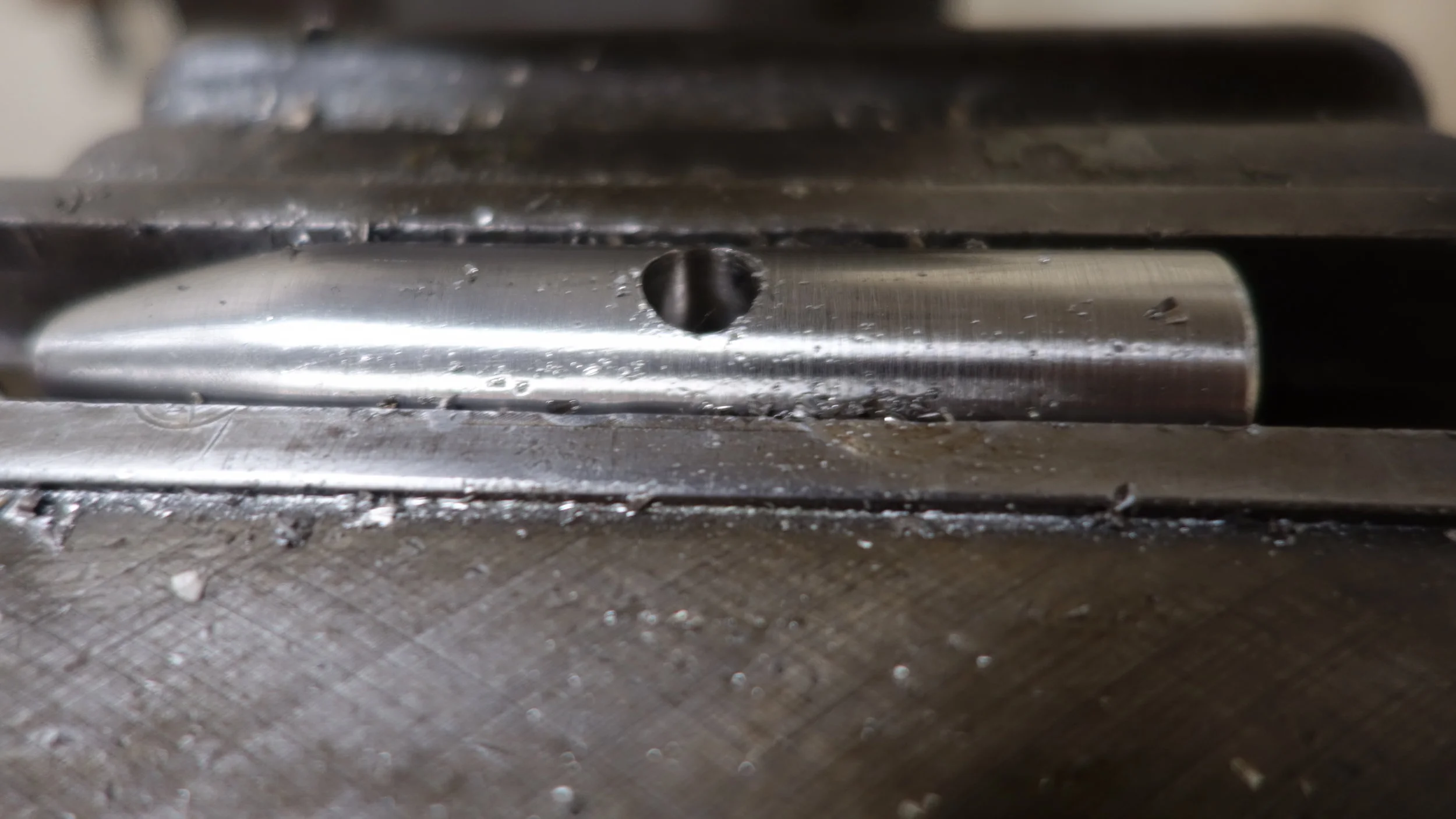

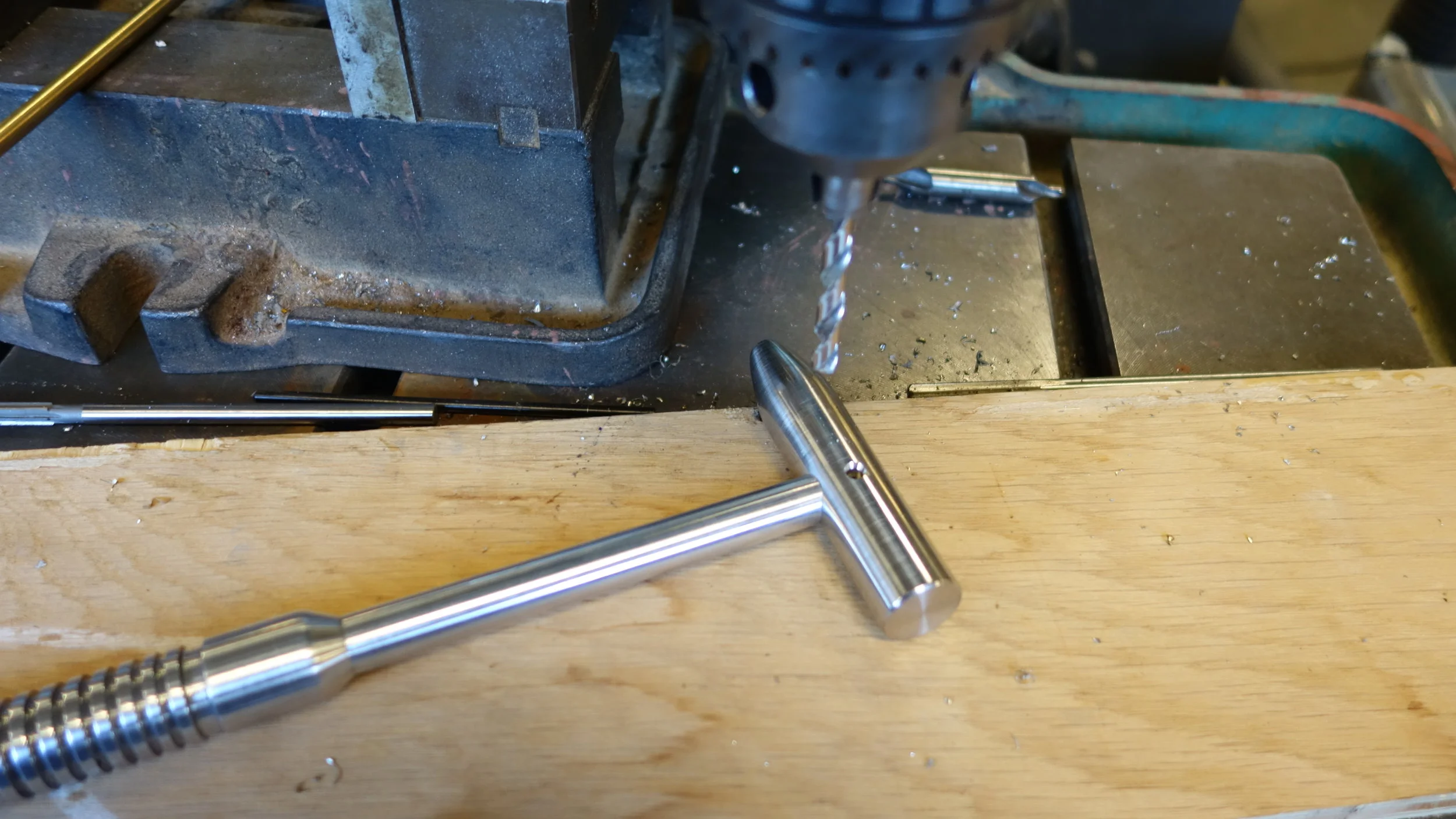

The head is composed of a single piece of 304 stainless steel (the hardest, toughest material readily available on campus) while the hammer handle I turned from the same piece of 2025 aluminum that I used for my first machinist's hammer. One of the big lessons from that project was that a screw-on head is not the way to go. People like to see if they can unscrew the two pieces, and I have a feeling that the threads are getting very slightly beat up from the pounding. Given the amount of use that hammer has been getting, that's fine for a prototype machinist's hammer, but less fine for something intended for rougher use. I had originally planned to press-fit the handle to the head using LN2, but after a bit of experimenting it seems like an aluminum-steel press fit isn't likely to hold up (at least given my current skill set), so I ended up using a brass pin to hold the head to the handle, and then peaning it into place.

Although I like the way the knurled handle performed on my last hammer, I decided to go with something a bit different for this one just to play around. The three larger gaps are positioned to fall under my thumb, middle, and ring fingers as they rest on the hammer. I am not yet sure how much I like this setup from an ergonomic standpoint, it may be that ridges hurt the hand under prolonged use, and I will update this document as I get a feel for that.

Update: The handle design does not seem to be an issue with light use. I am pretty sure it would be if I spent the day driving nails, but the soft (relatively) stainless steel head means I'm not planning to use it that way in any case. . A bit more research (and some help from the wonderful people on the hobby-machinist forums) suggests that wood might be a better choice for that kind of pounding in any case.