Summary:

Roasting marshmallows with the torch. I thought this worked rather well, though folks who prefer their marsh mellows more browned and less crispy might disagree.

This flame thrower was a marvelous one-day-build, created with the fantastic Emma Kerr, for an icecream and marshmallows party later the same day.

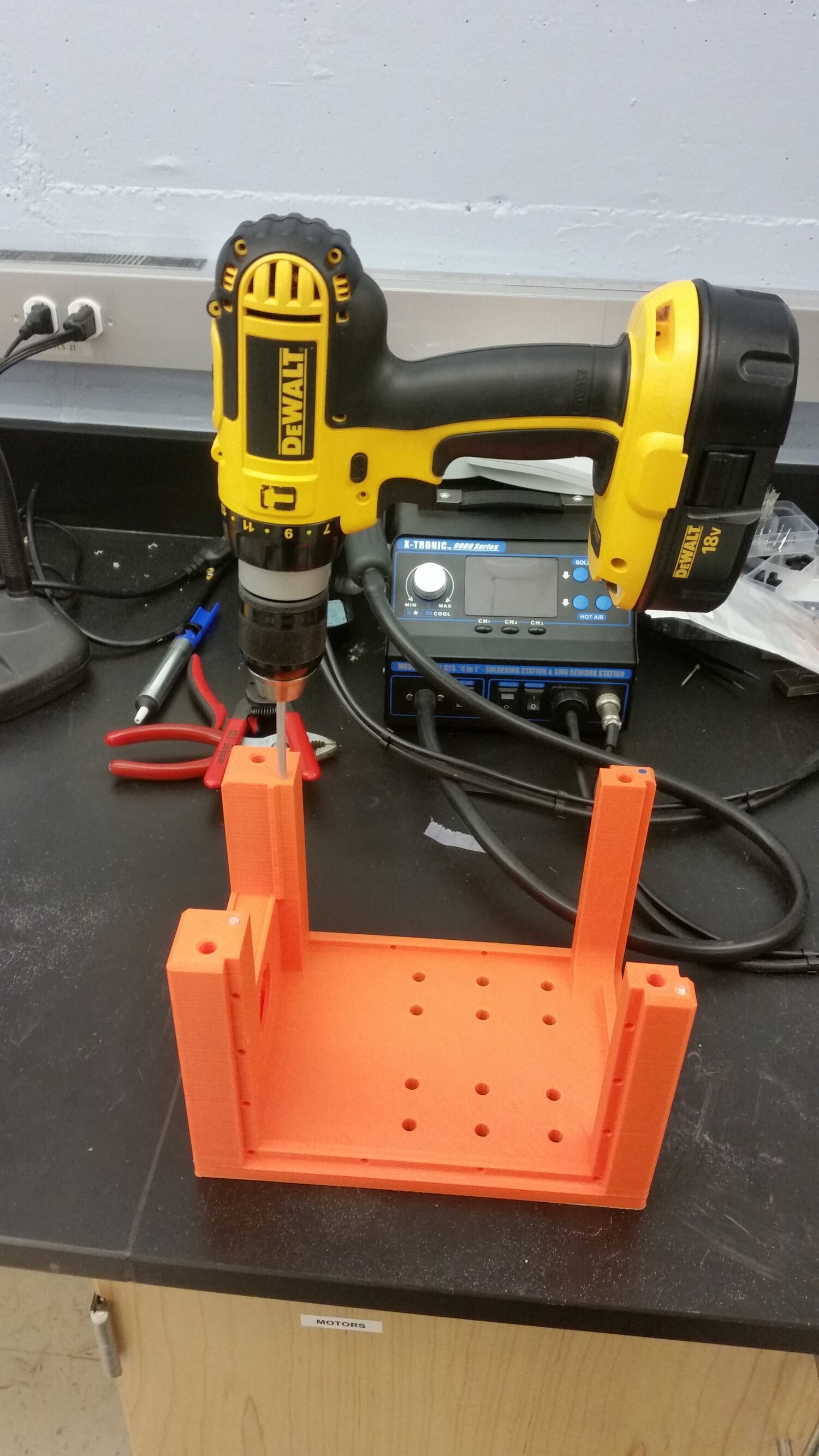

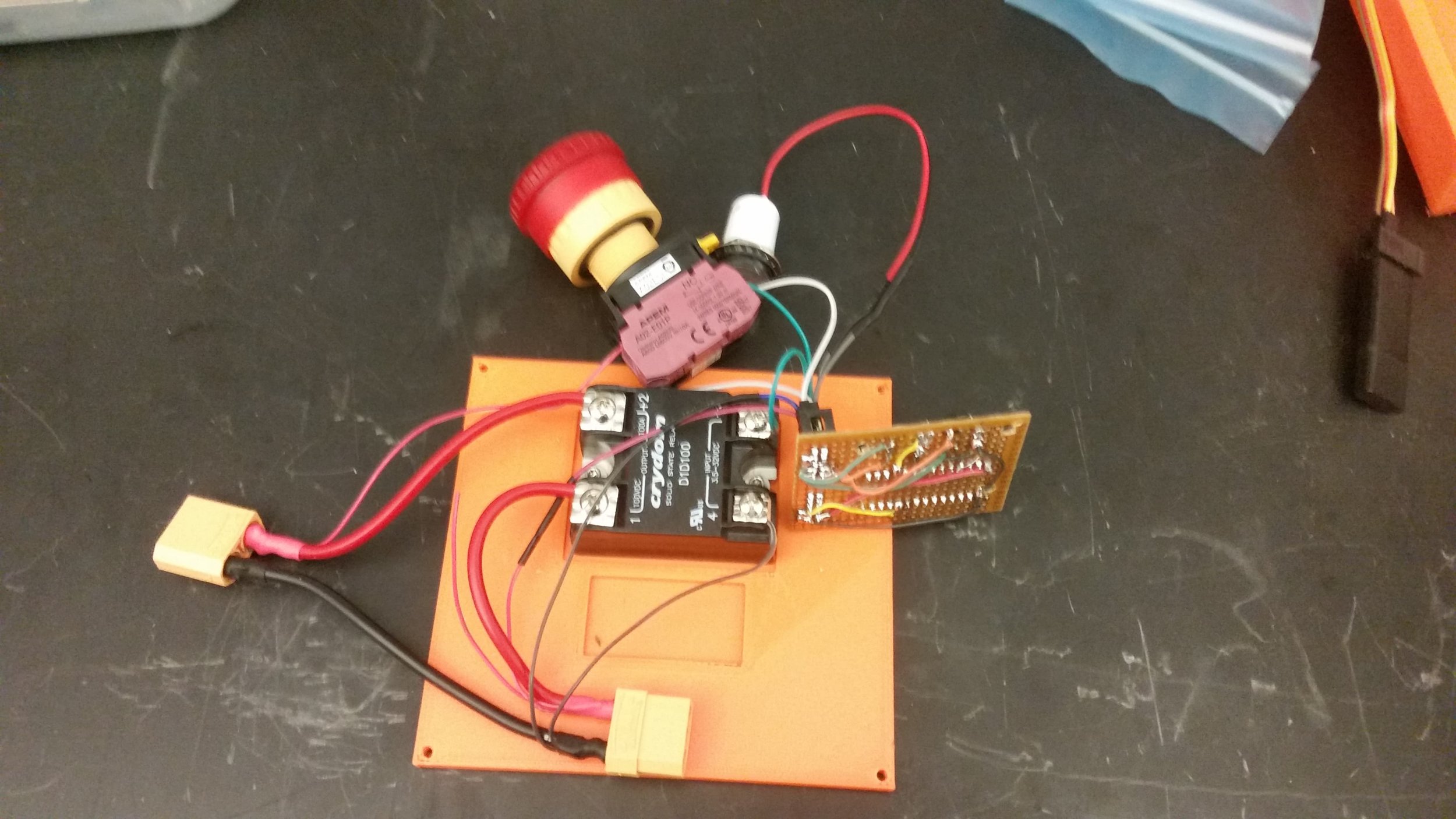

It uses Sterno butane canisters as the main fuel source and an olive oil lamp as the pilot light. The calk gun is used to release butane from the canister onto the pilot light where it ignite. I particularly like this design, because it can be created entirely from home depot parts, and requires only a torch and drill to fabricate.

Note: This project, like all fire projects, was operated on private property with the permission of the owners. Appropriate PPE and fire suppression equipment are very important if you plan a similar build.

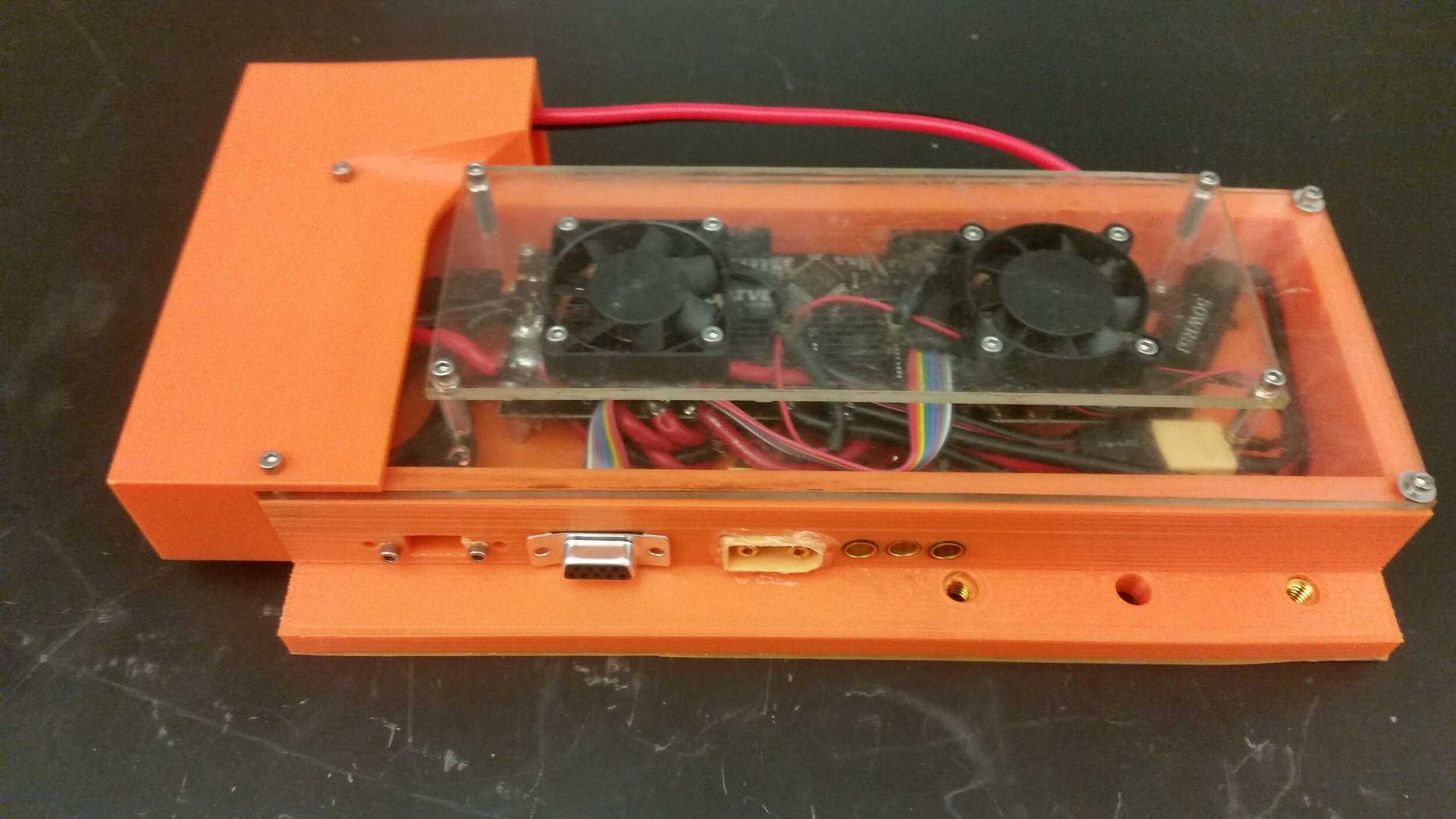

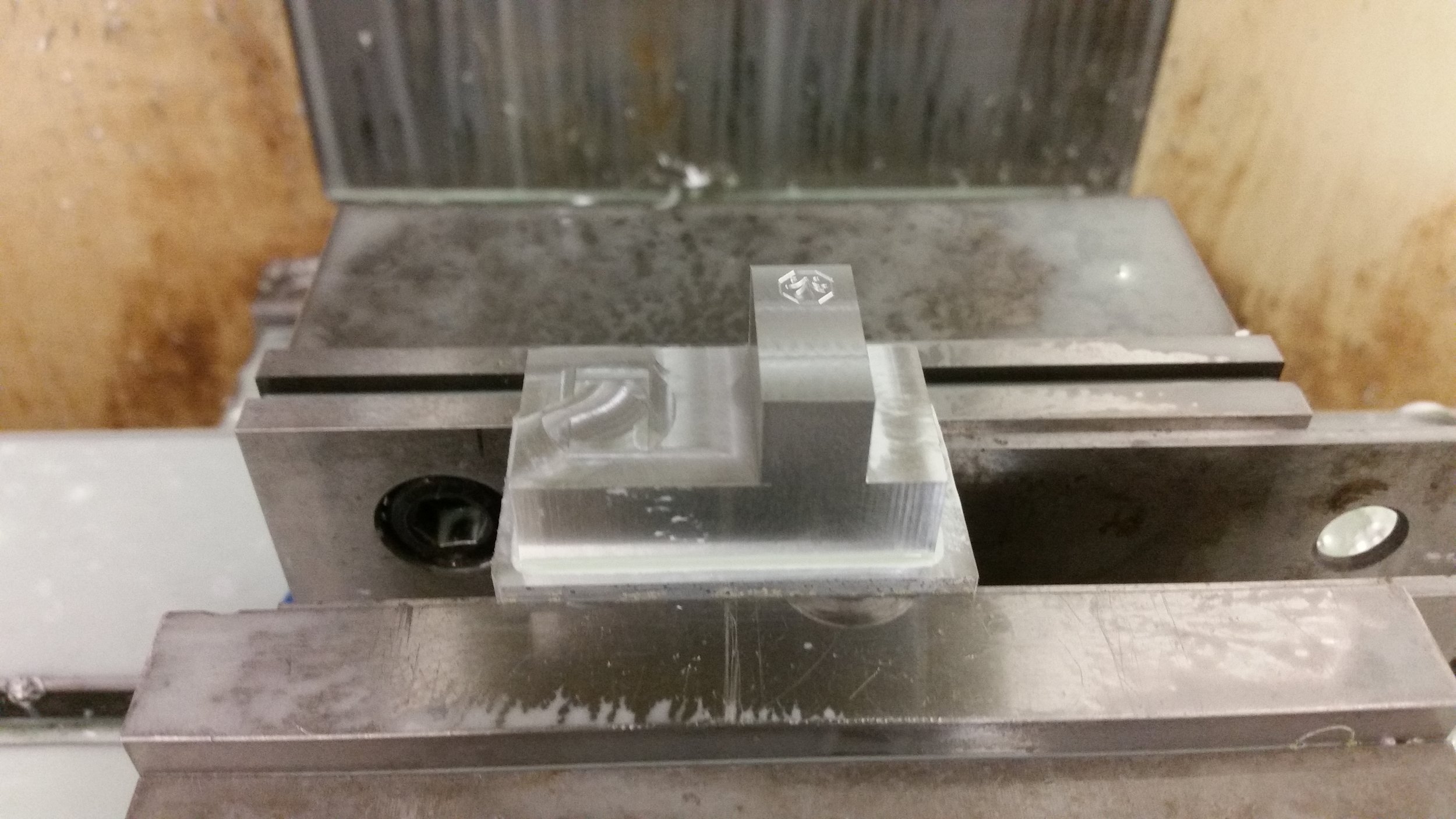

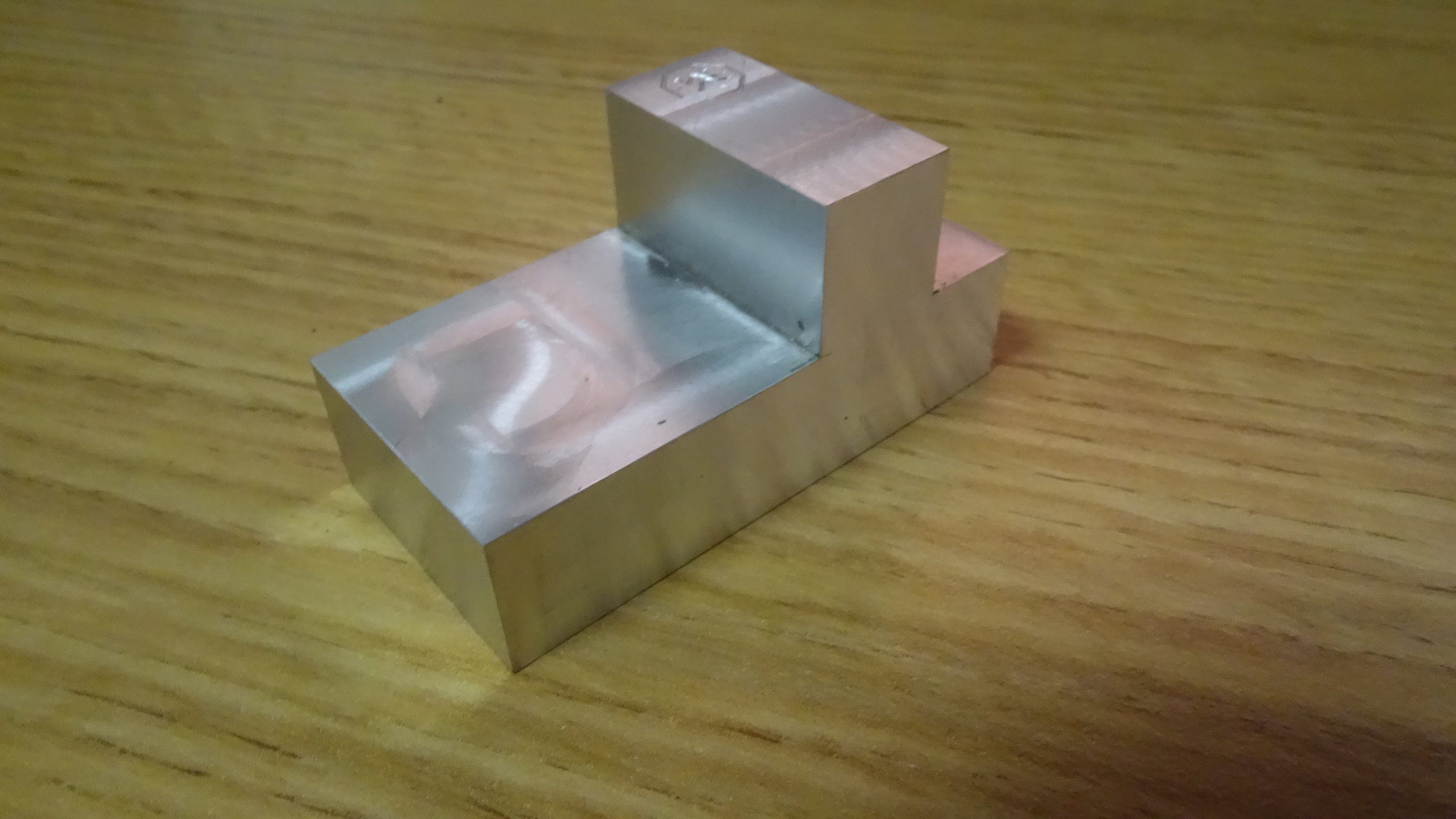

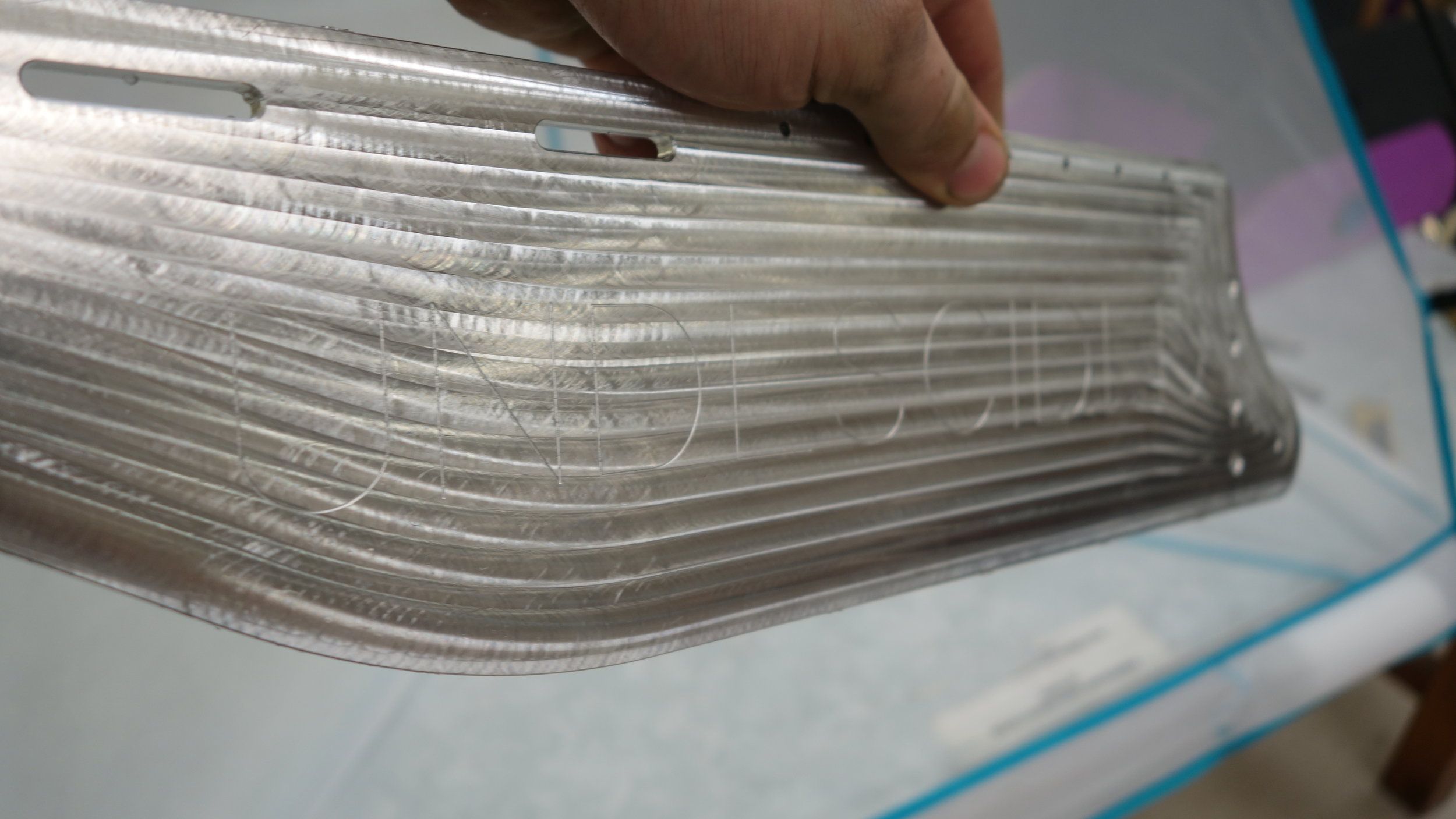

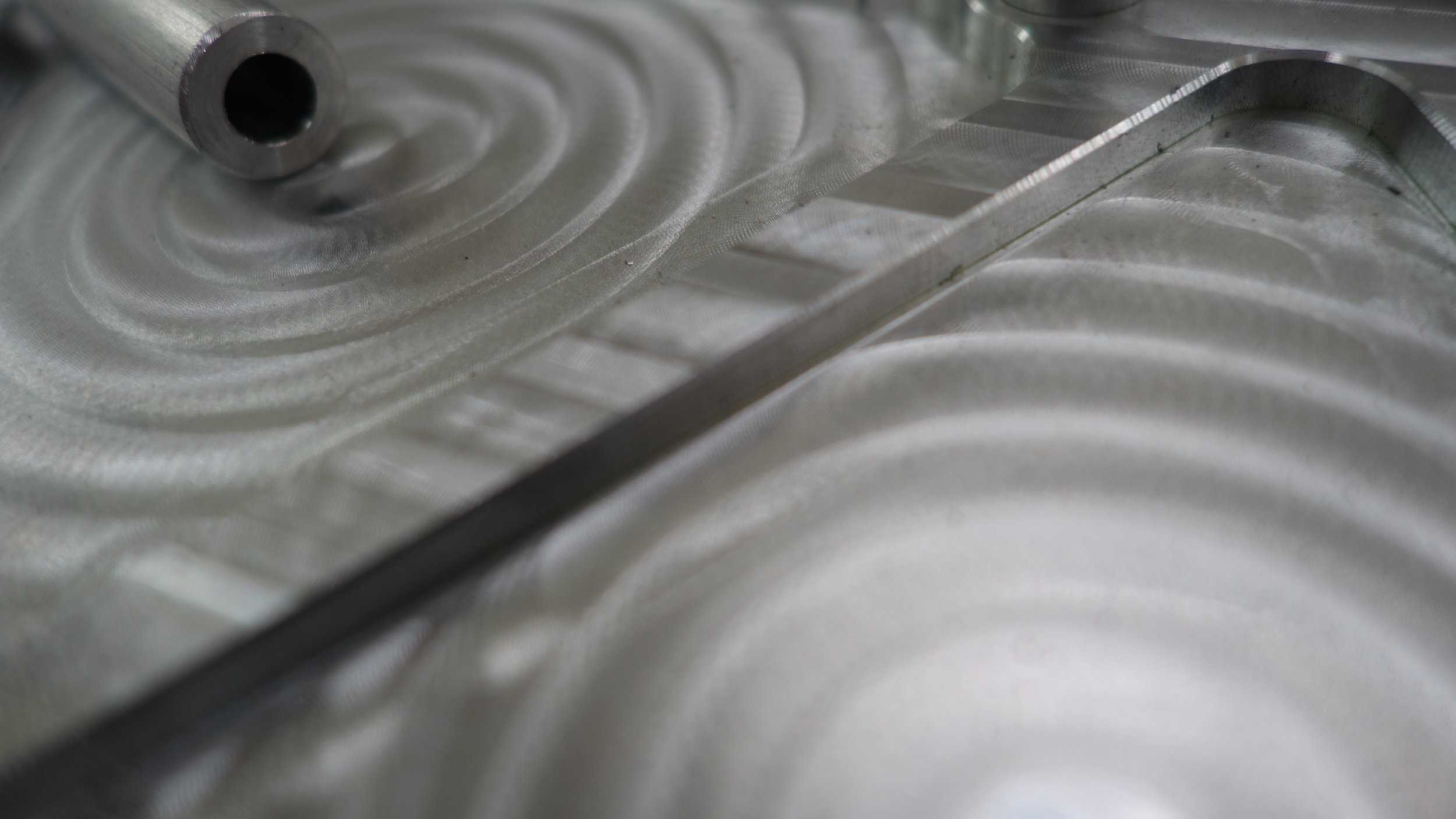

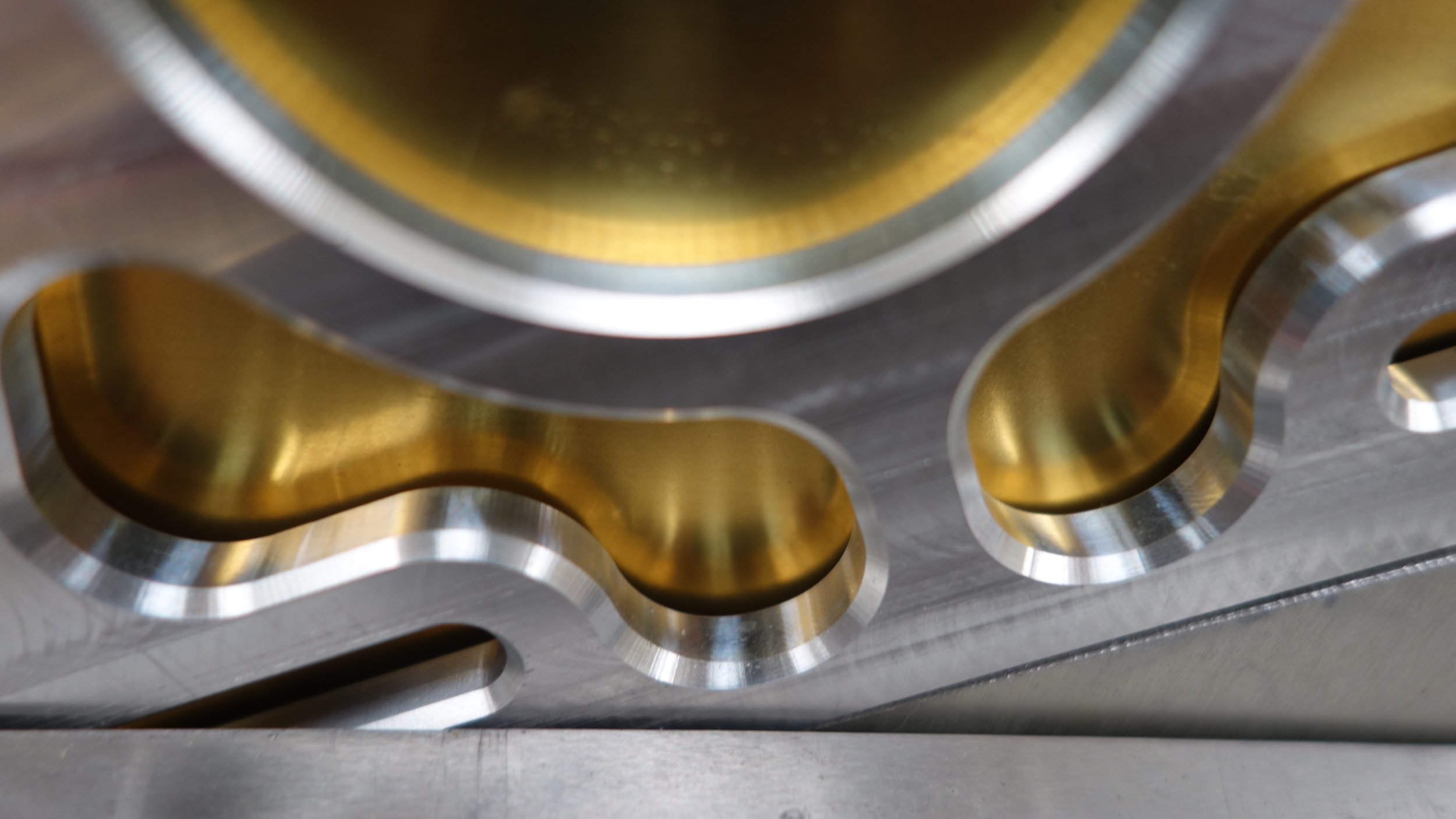

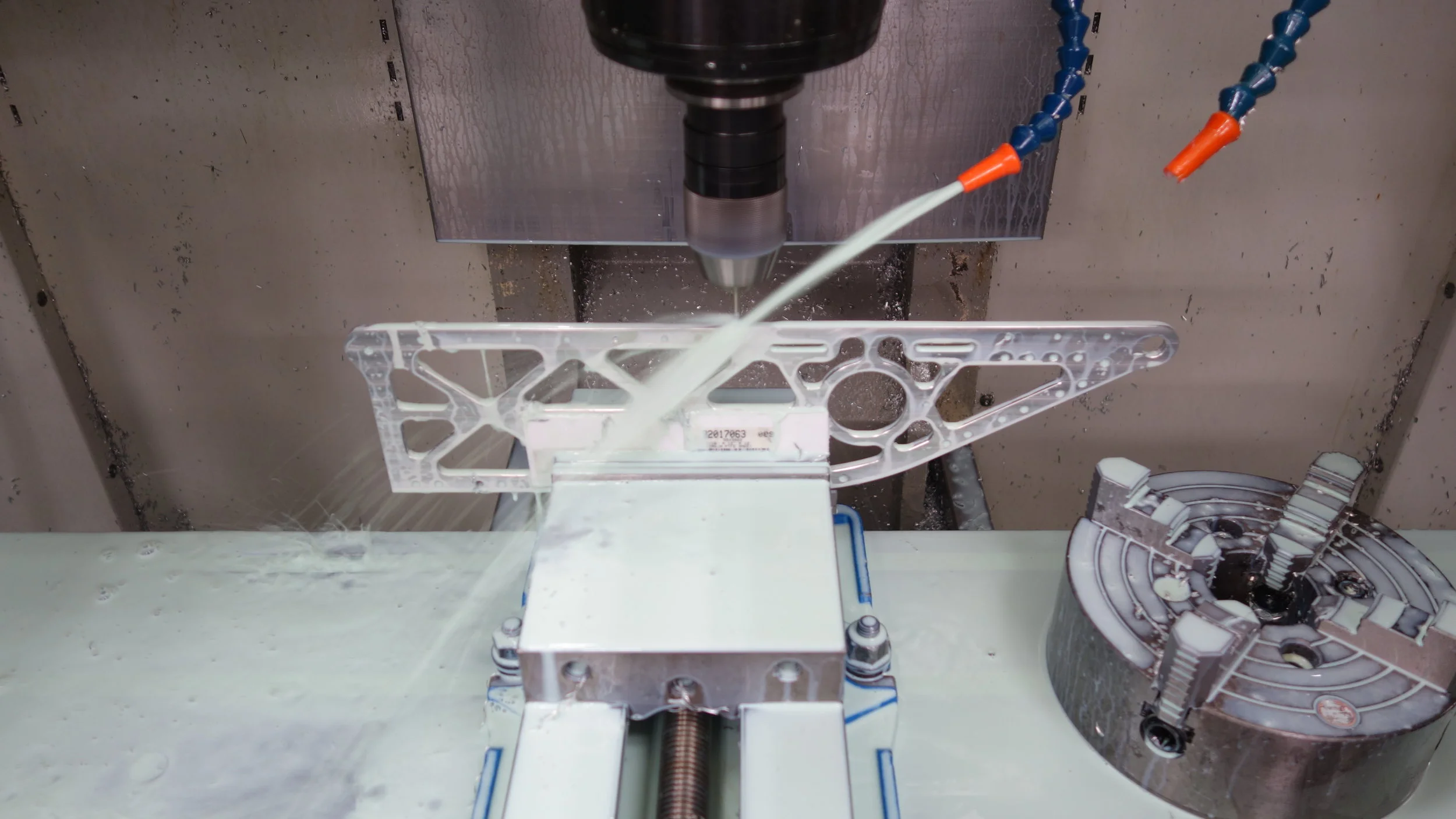

The front of the torch is an oil lamp. This is made a 90 degree bend, and a short length of copper pipe sealed at one end. I have found that olive oil and Tiki oil both work well, although the Tiki oil does light better. It is important that the soldered connection between the bend and the reservoir be well sealed for obvious reasons. If possible the wick should bend into the reservoir, but it works fine with just a short length in the 90 degree section.

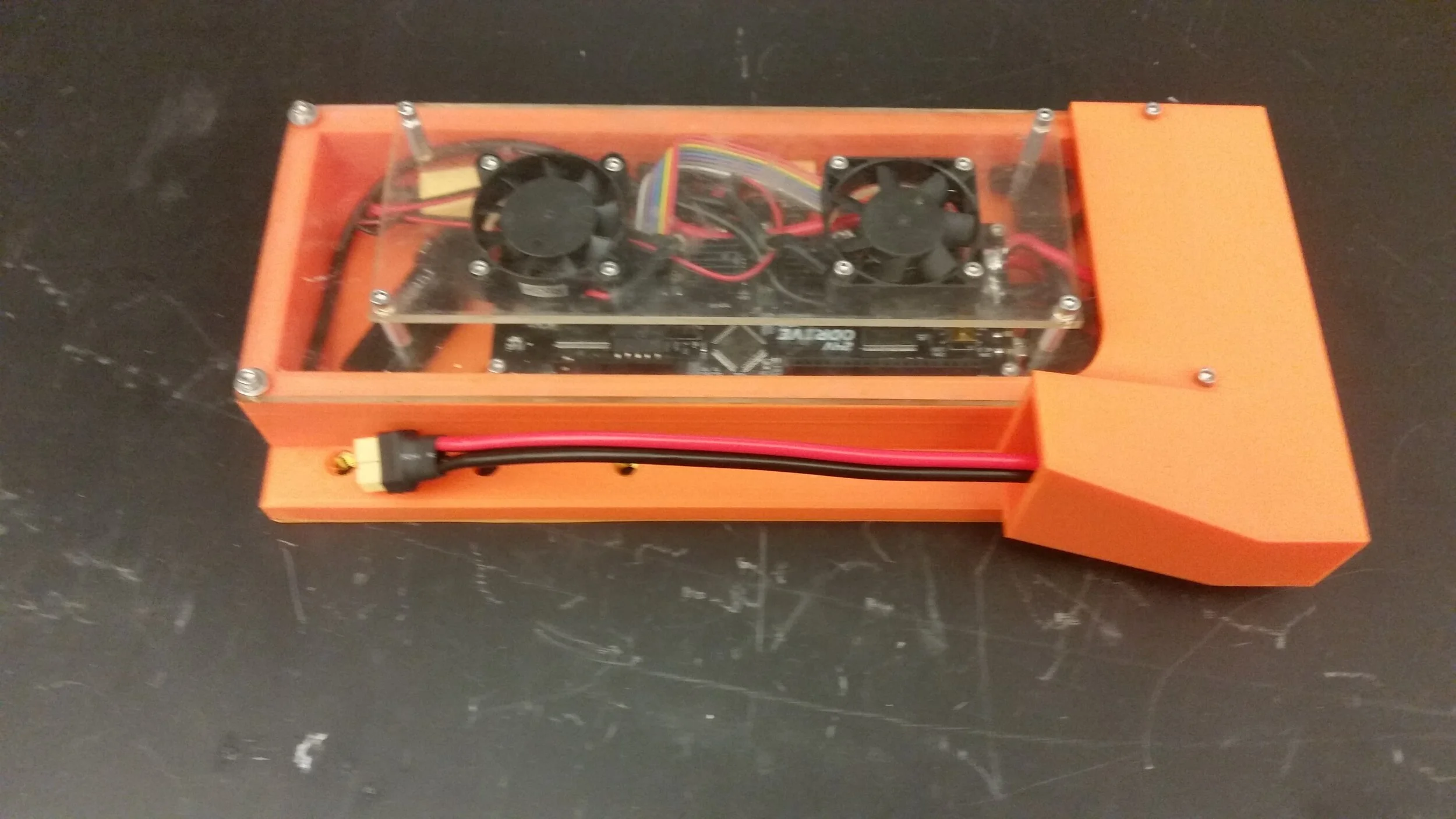

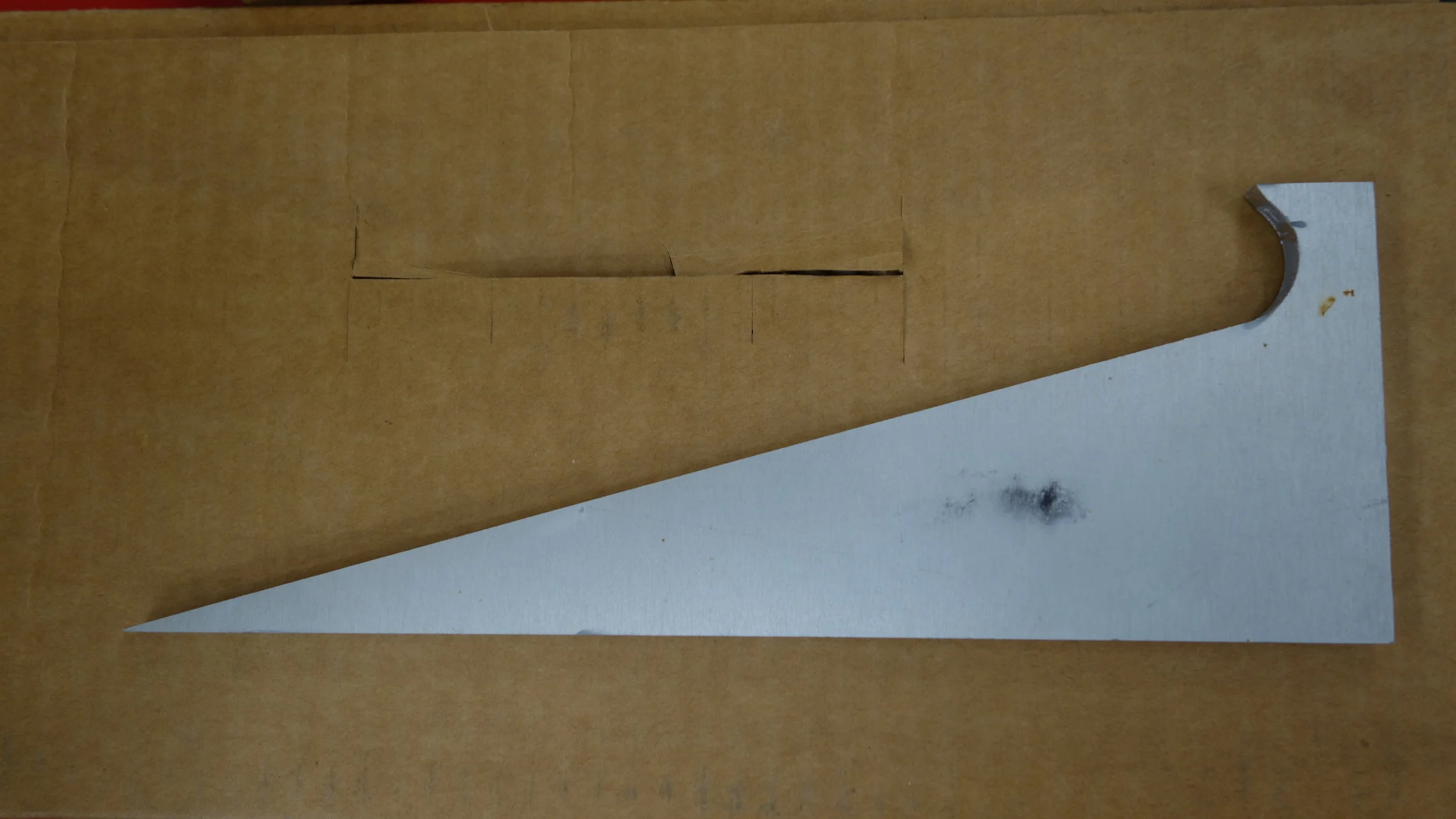

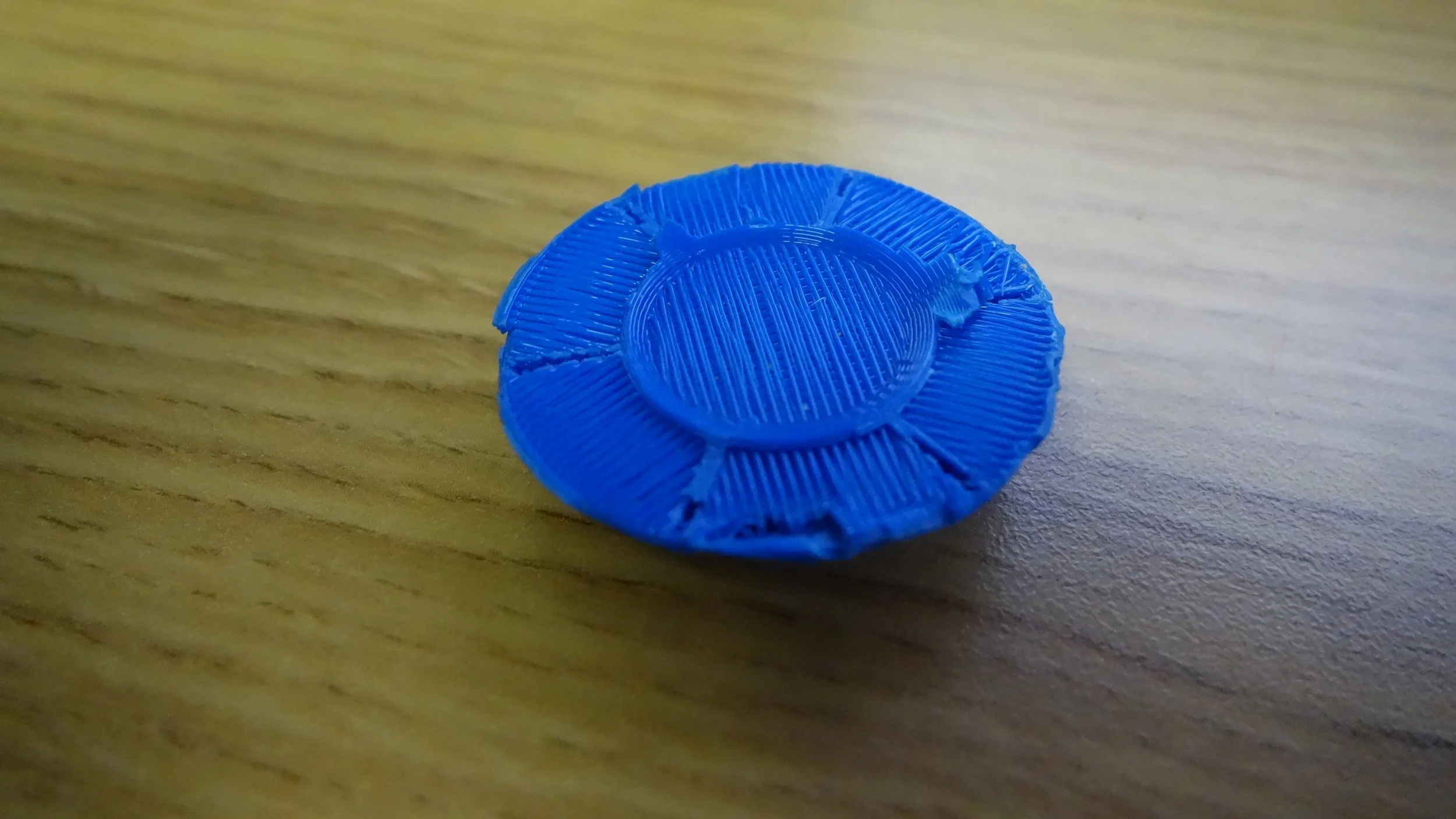

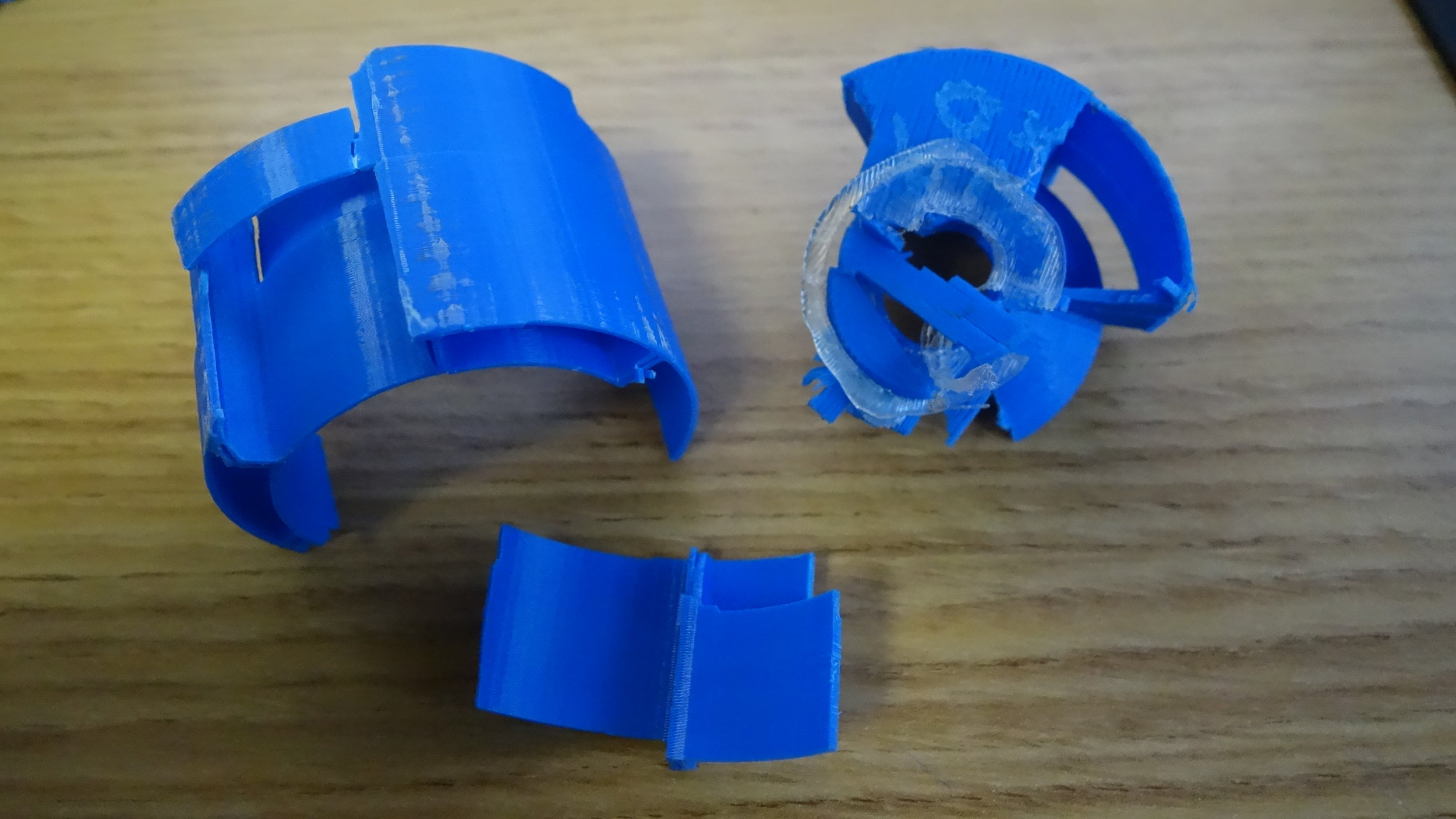

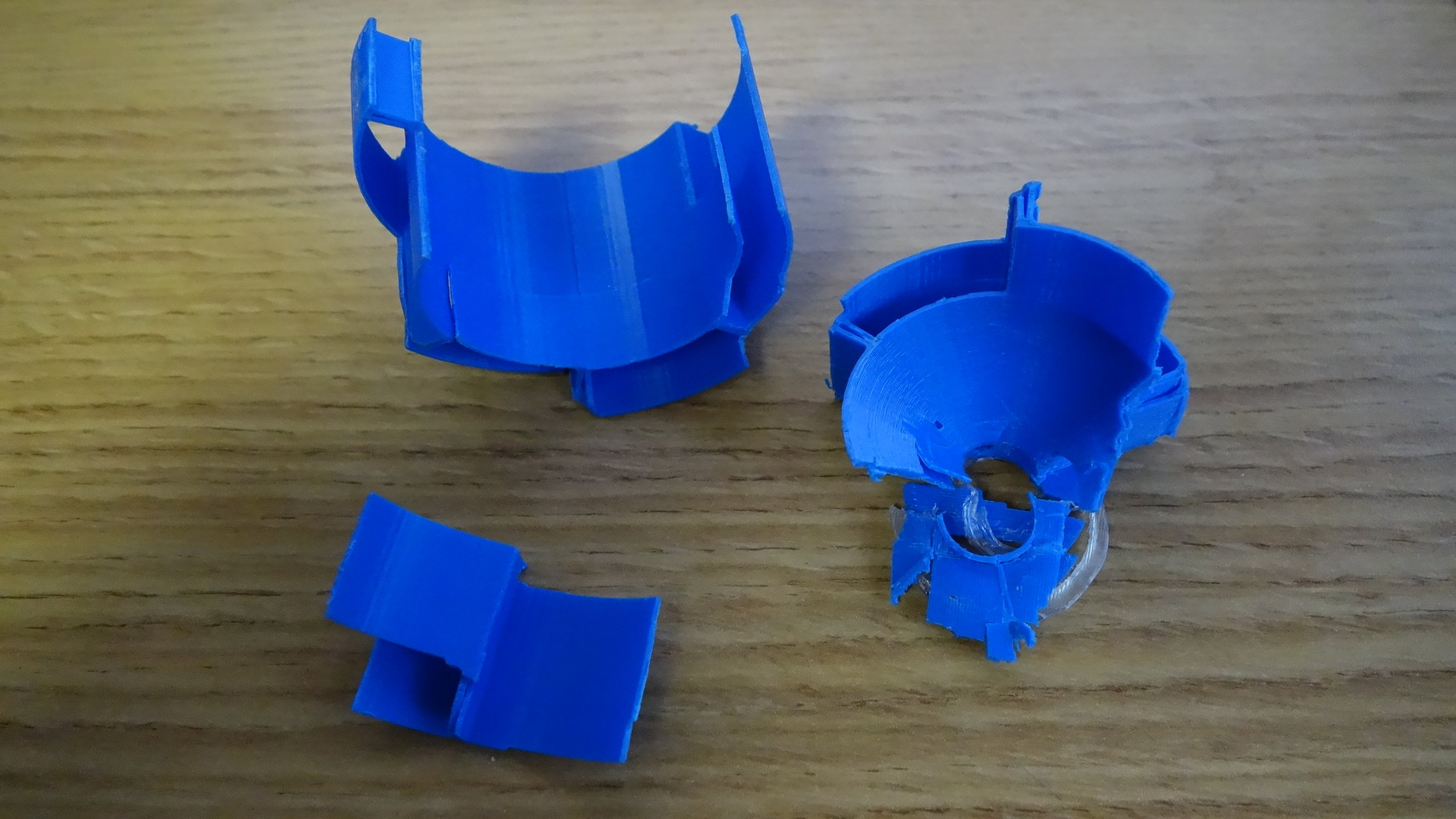

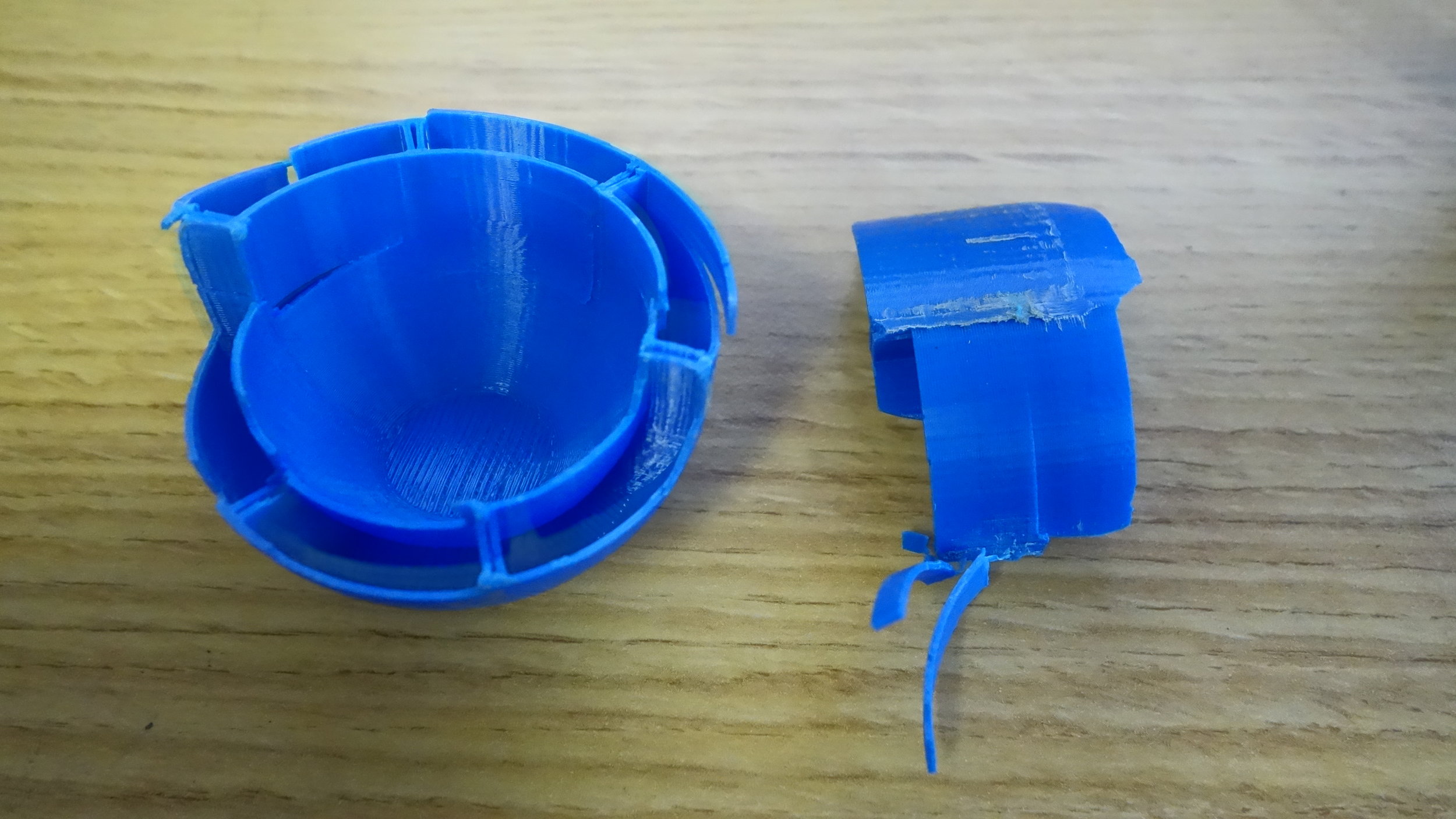

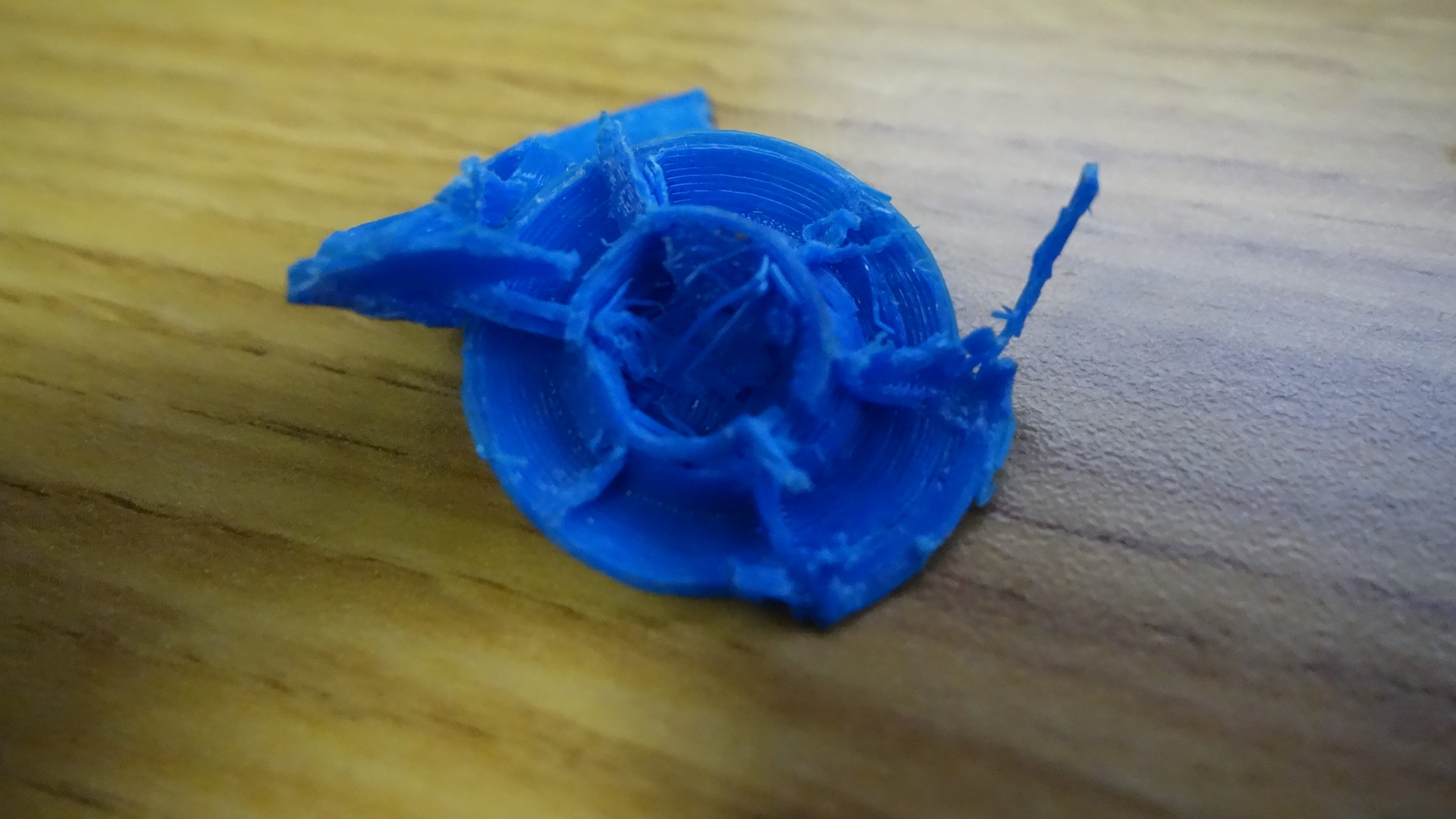

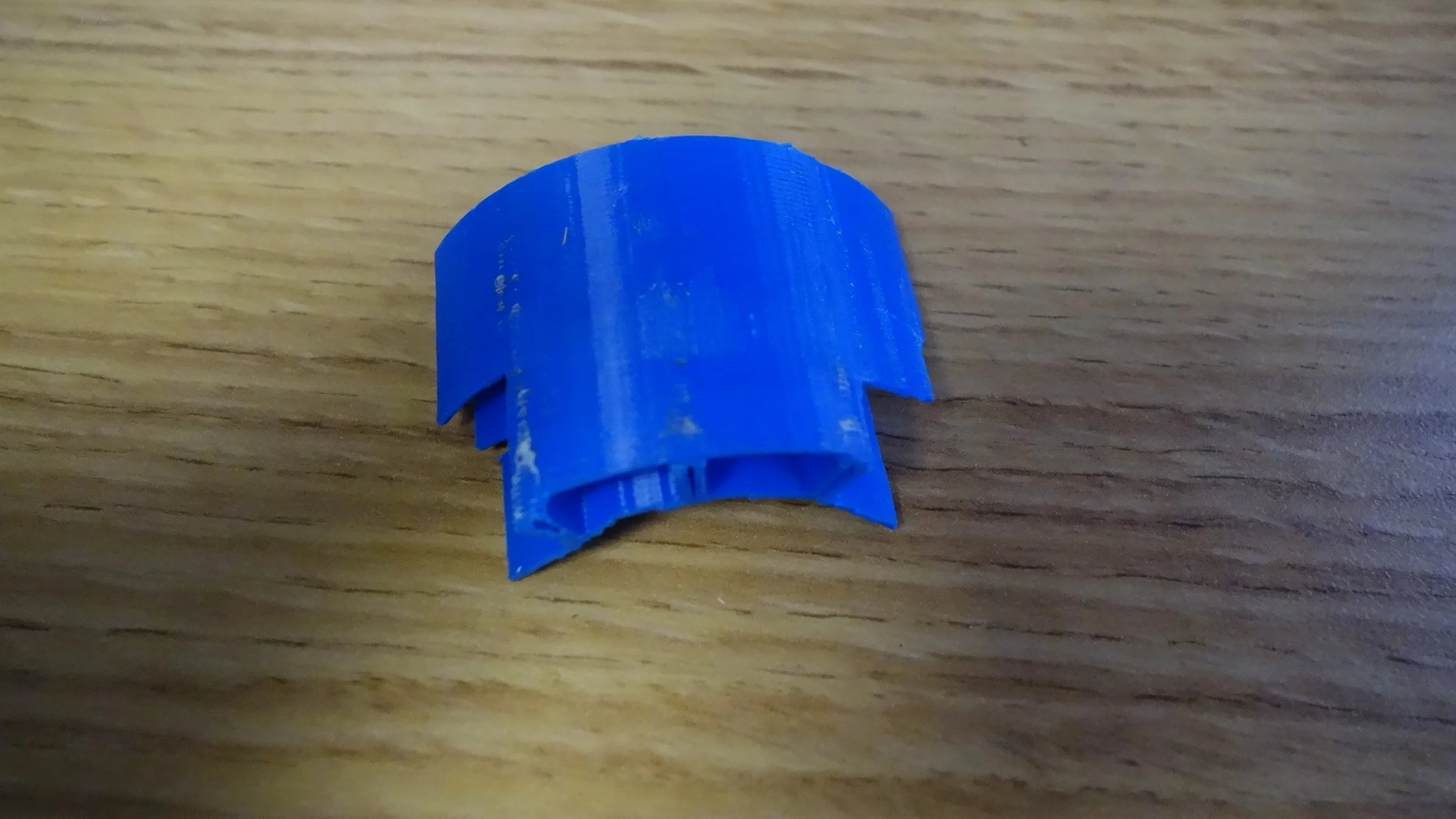

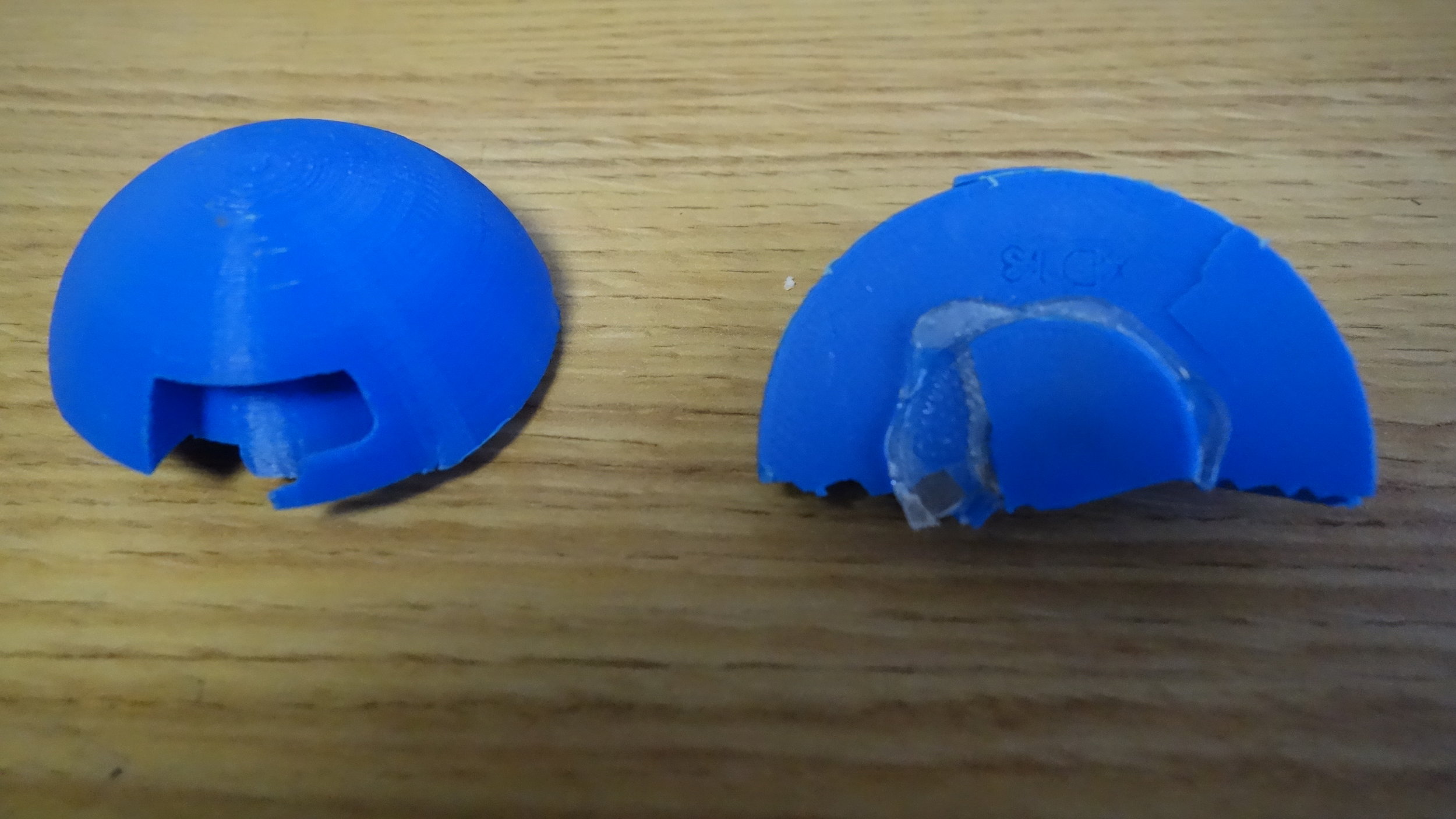

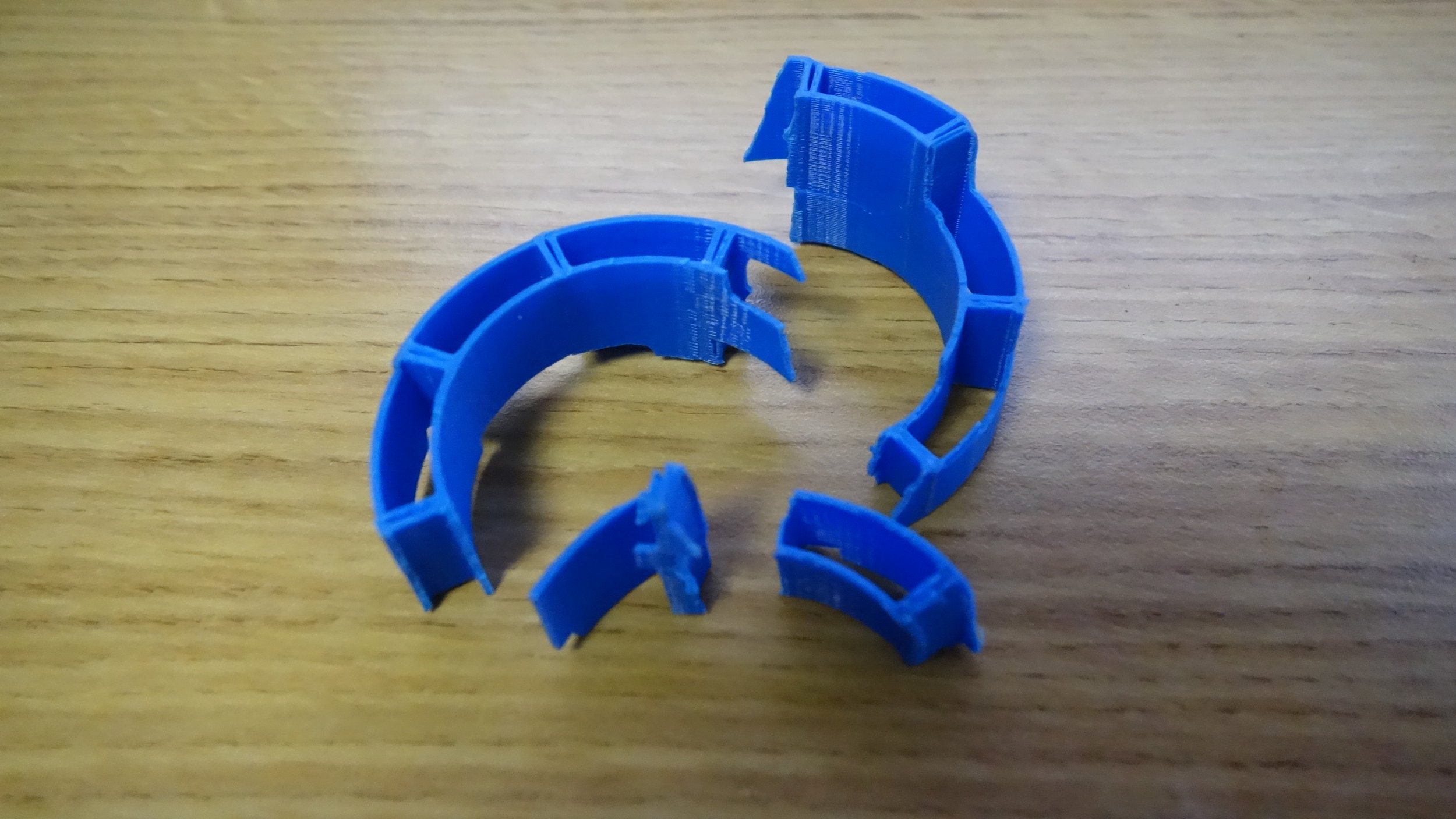

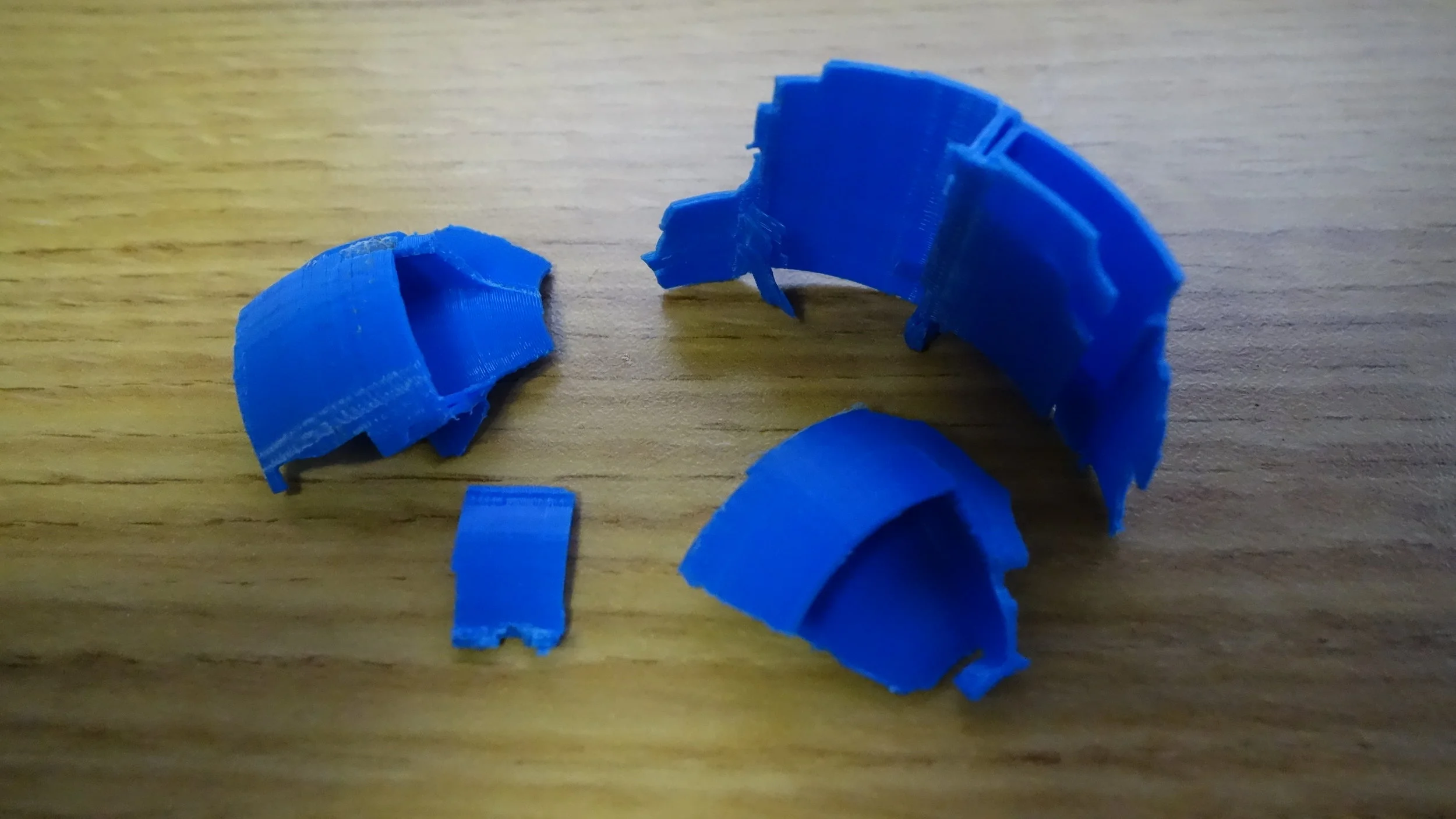

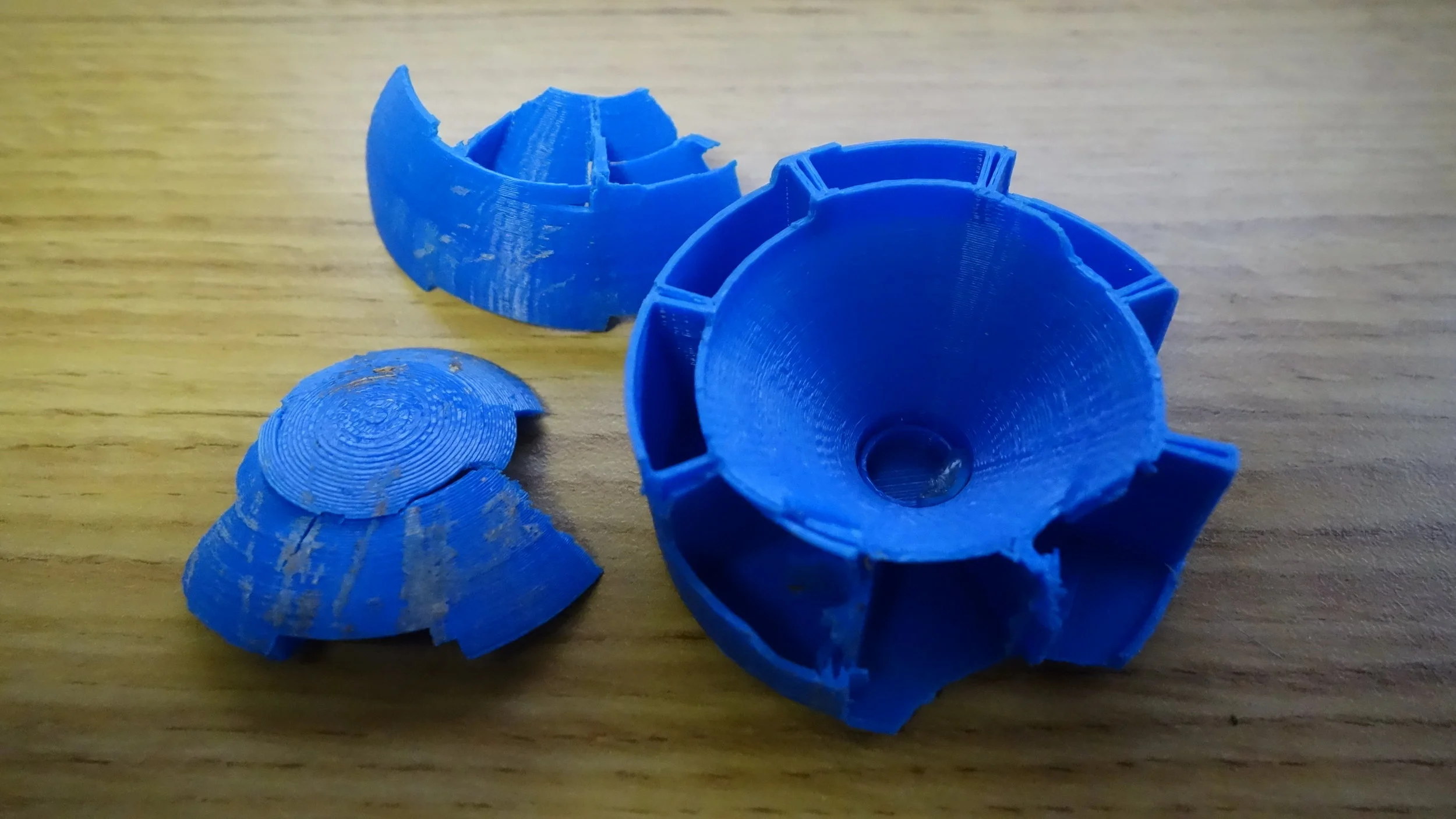

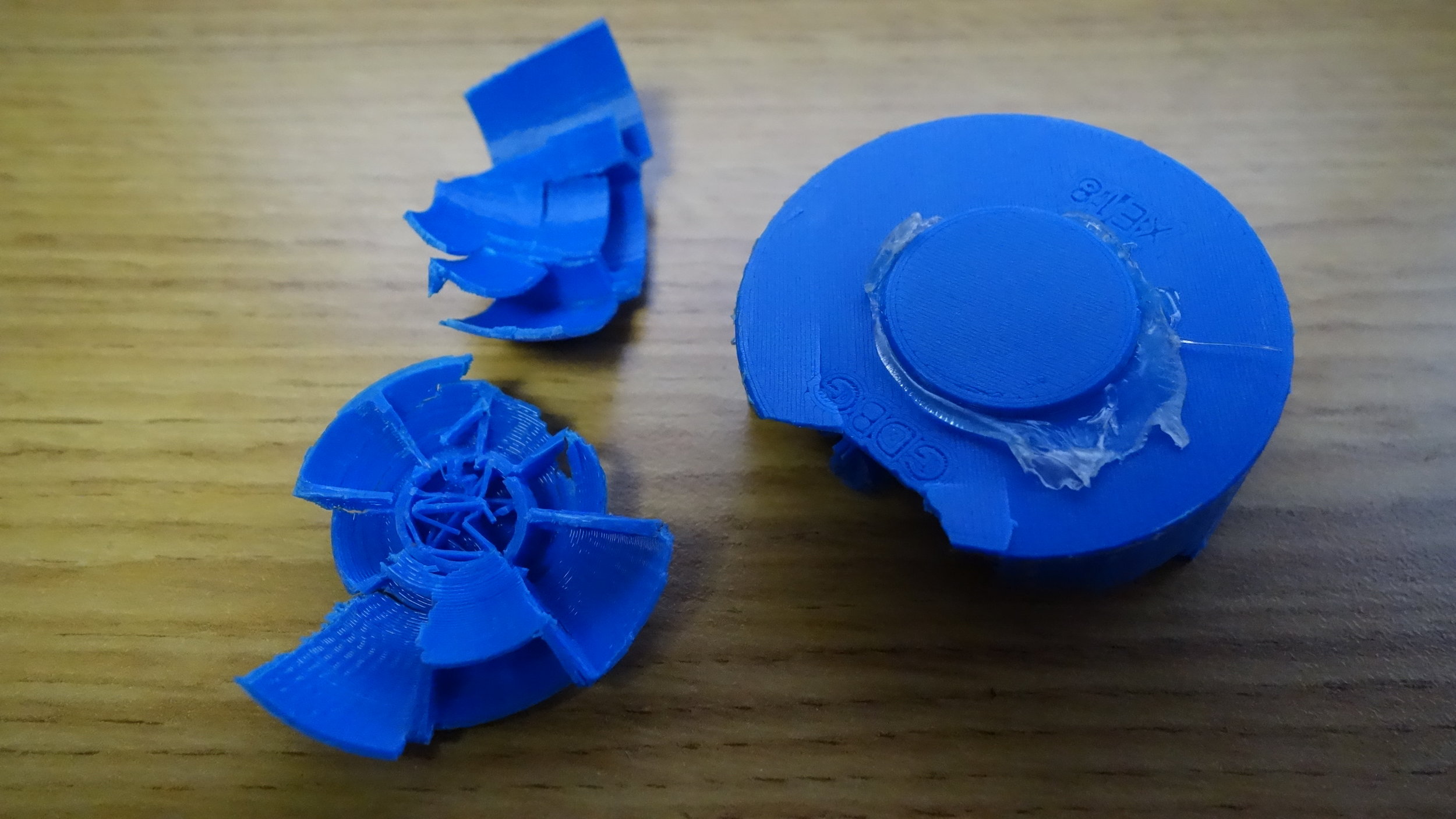

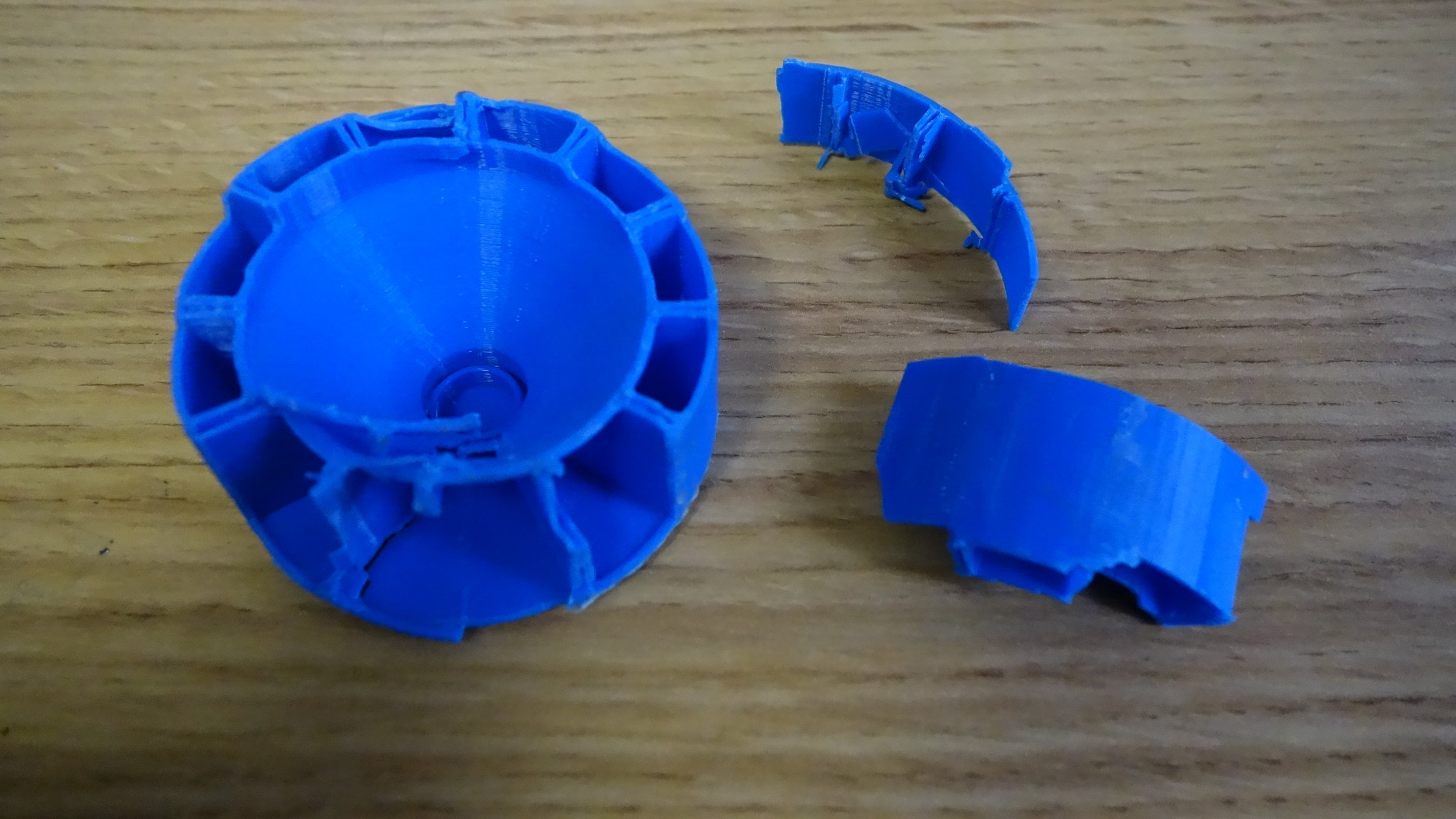

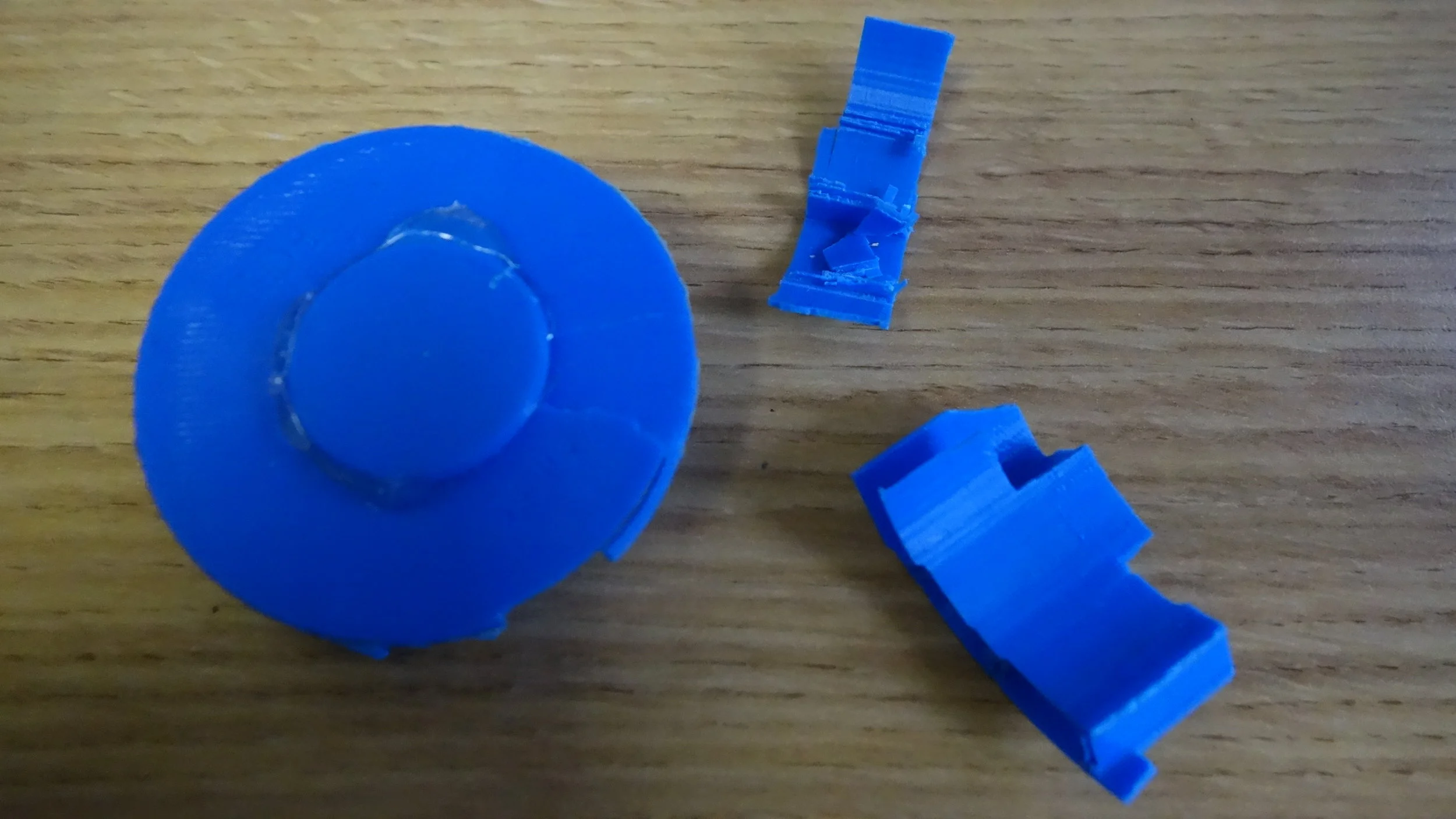

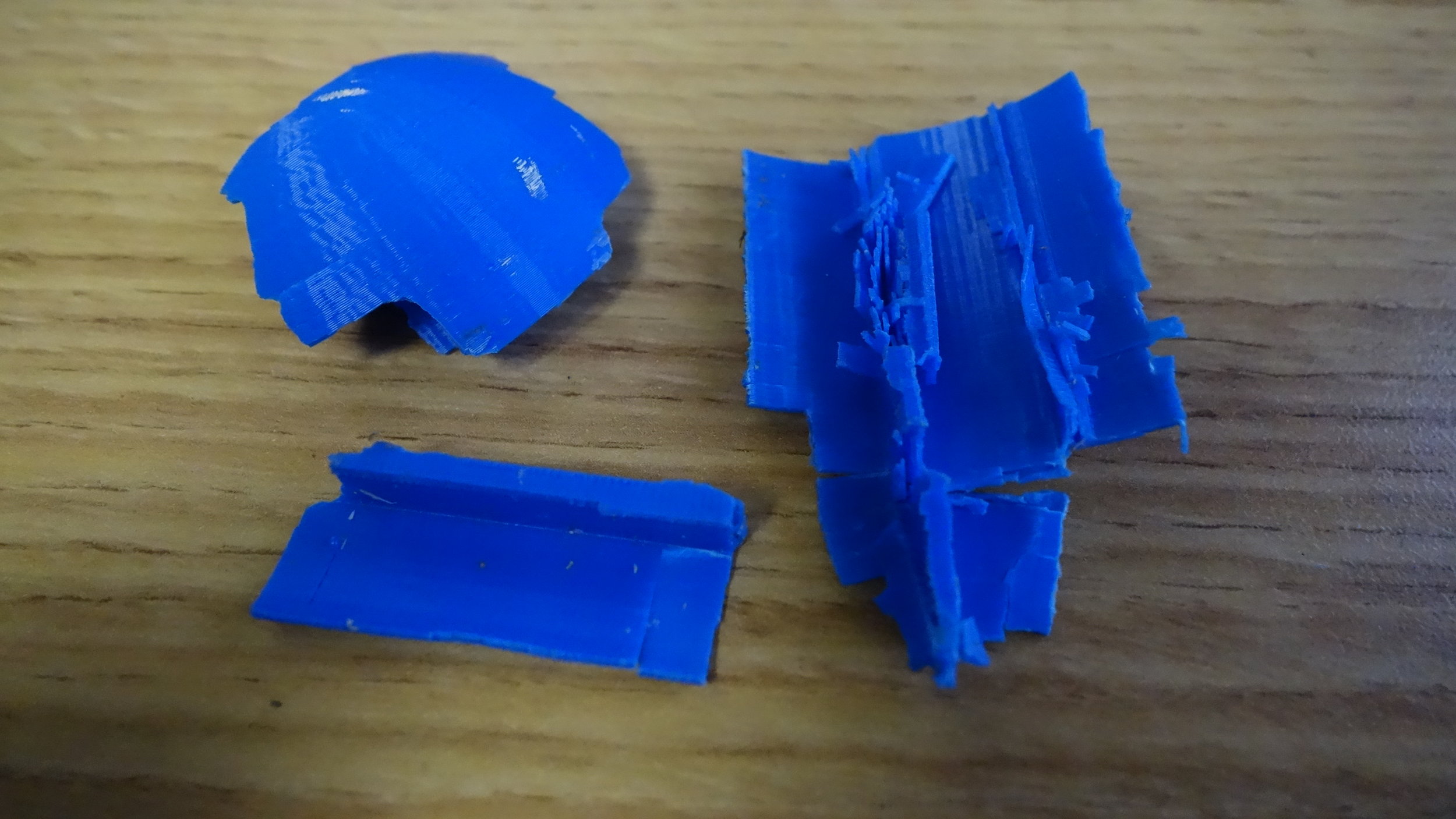

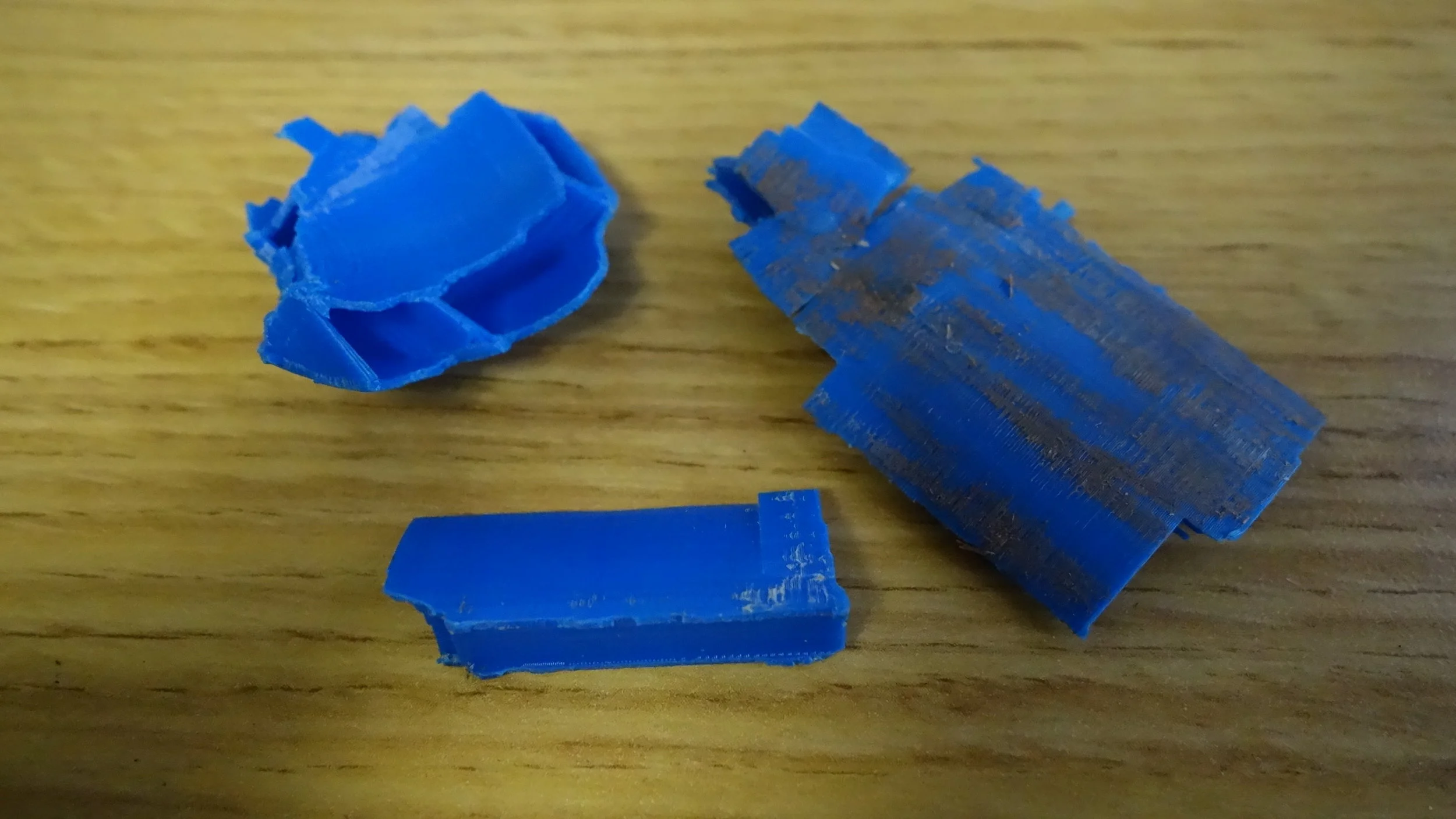

I used a 3D printed disk with a double tapered hole as the output. This works well, but is fundamentally a consumable part (Order of 3 canisters before change). The main issue that it can slightly impede the flow of butane and that when this happens the disk tends to melt a bit when the fire goes out. This can be solved either by using an aluminum disk, or by changing to a fuel type that has a tapered tip. With that said, I am pretty happy with this as a consumable for now.

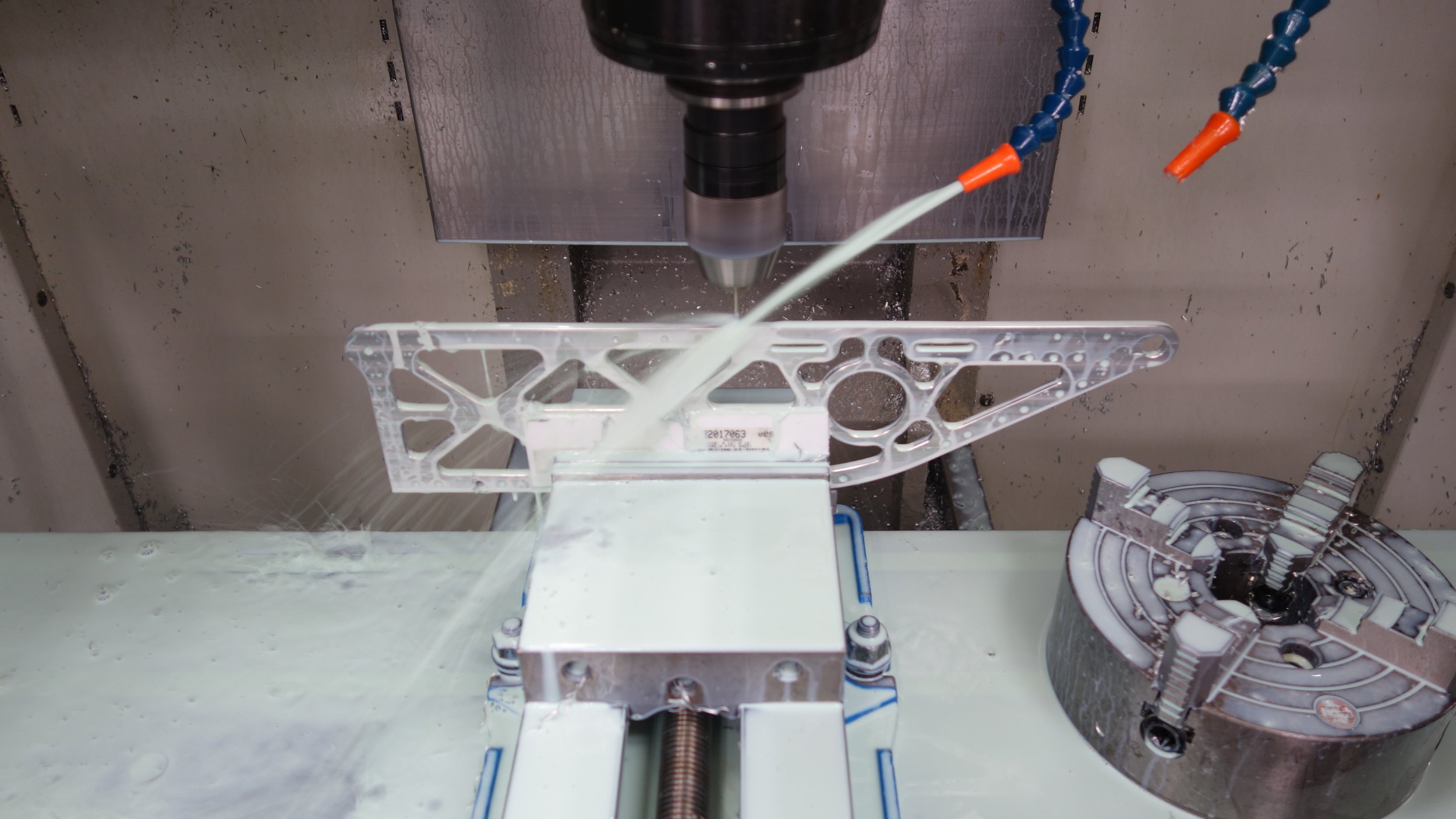

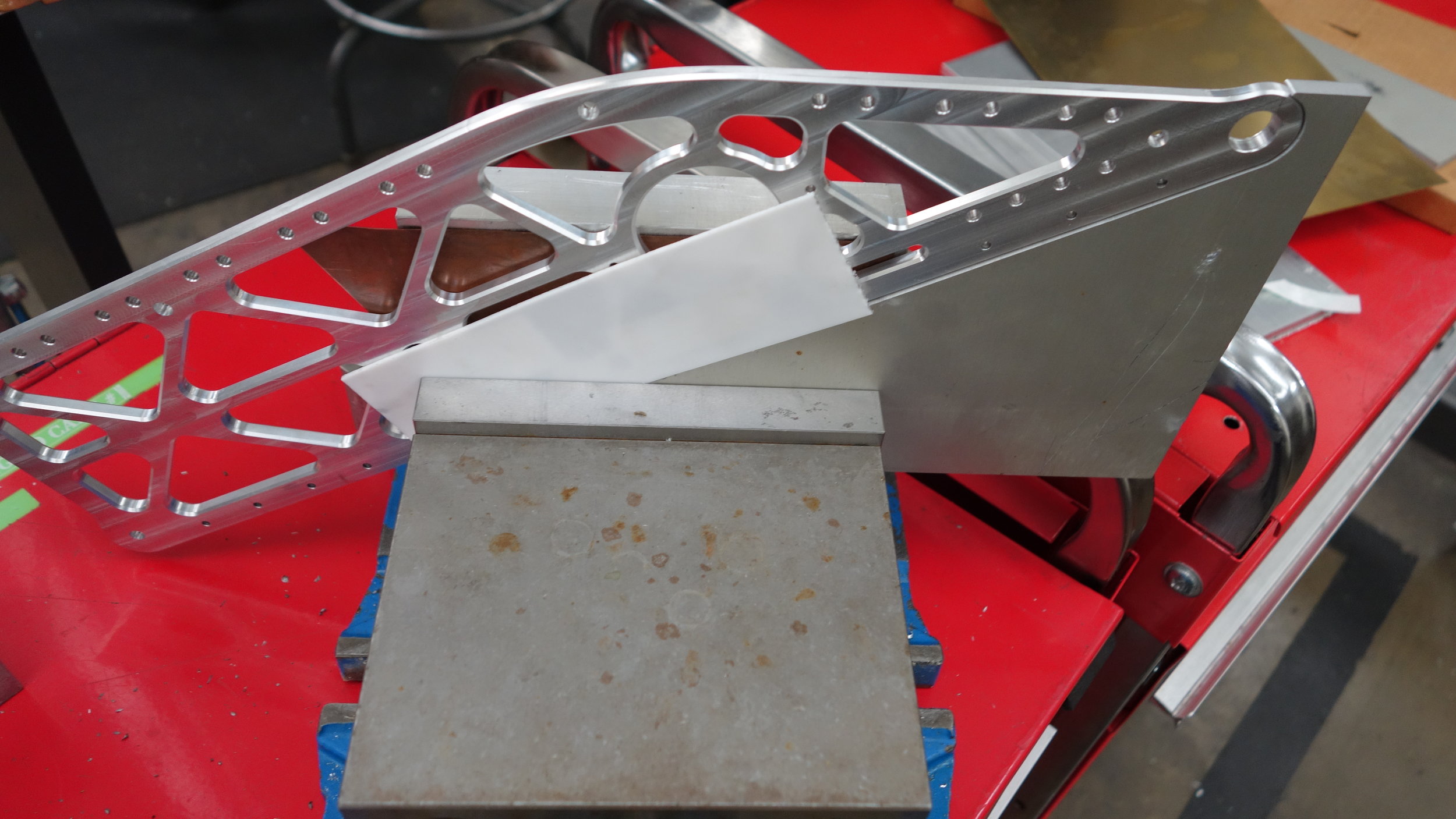

The forward handle is connected to the rest of the frame by a t-joint. Placing the forward handle slightly before the nozzle outlet provides a lot of control, but does mean welding gloves are more or less mandatory for operating the thrower two handed.

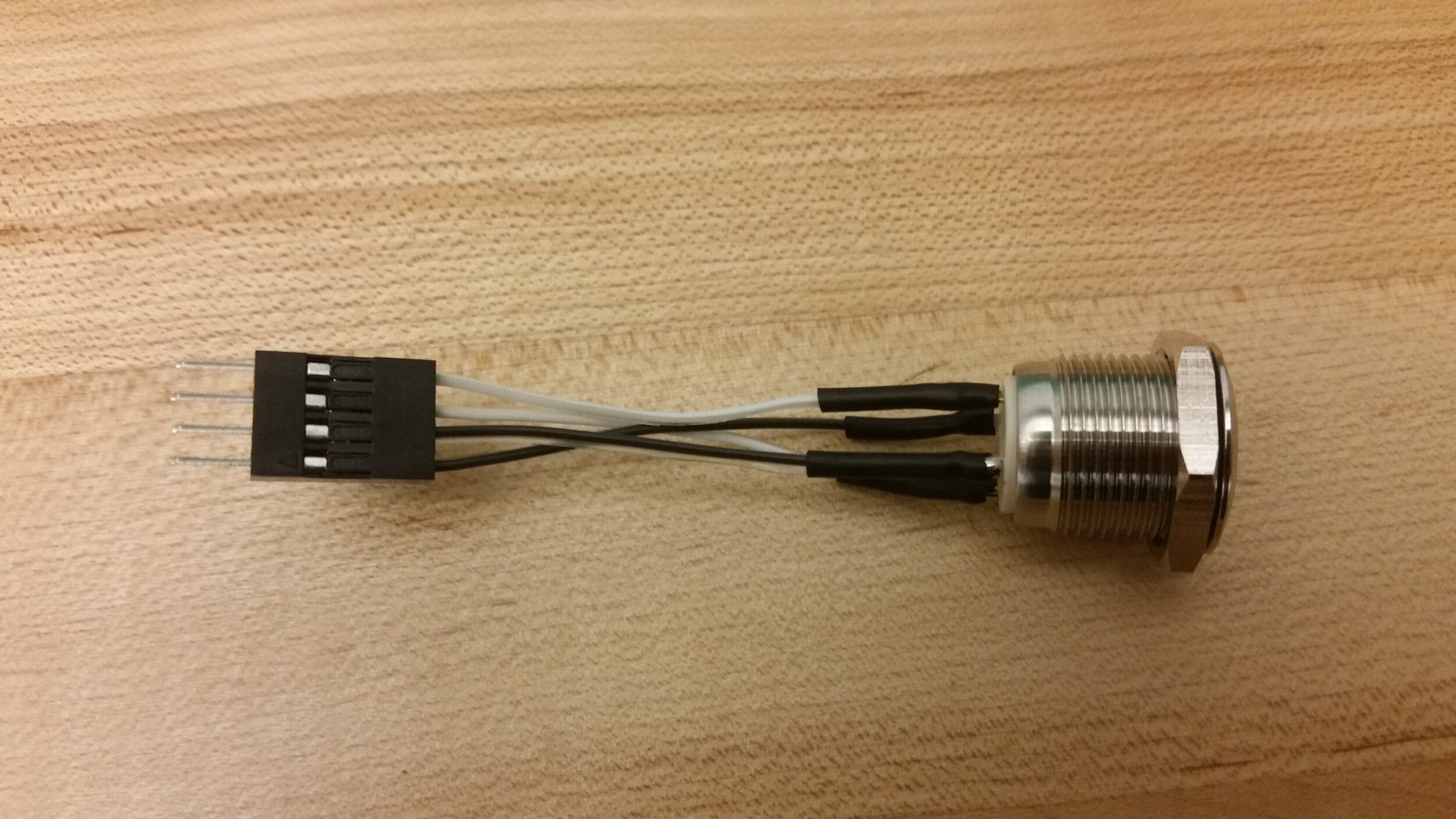

The handle and pilot assembly is connected to the chalk gun by two 4-40 socket head cap screws running from inside the chalk gun assembly to tension nuts on the underside of the pipe. I was surprised to discover that this proved more than adequate even without additional supports.

For the pilot wick I use a standard Tiki lamp wick. I’ve found this works well with a variety of fuels, plus they are available pretty much everywhere.

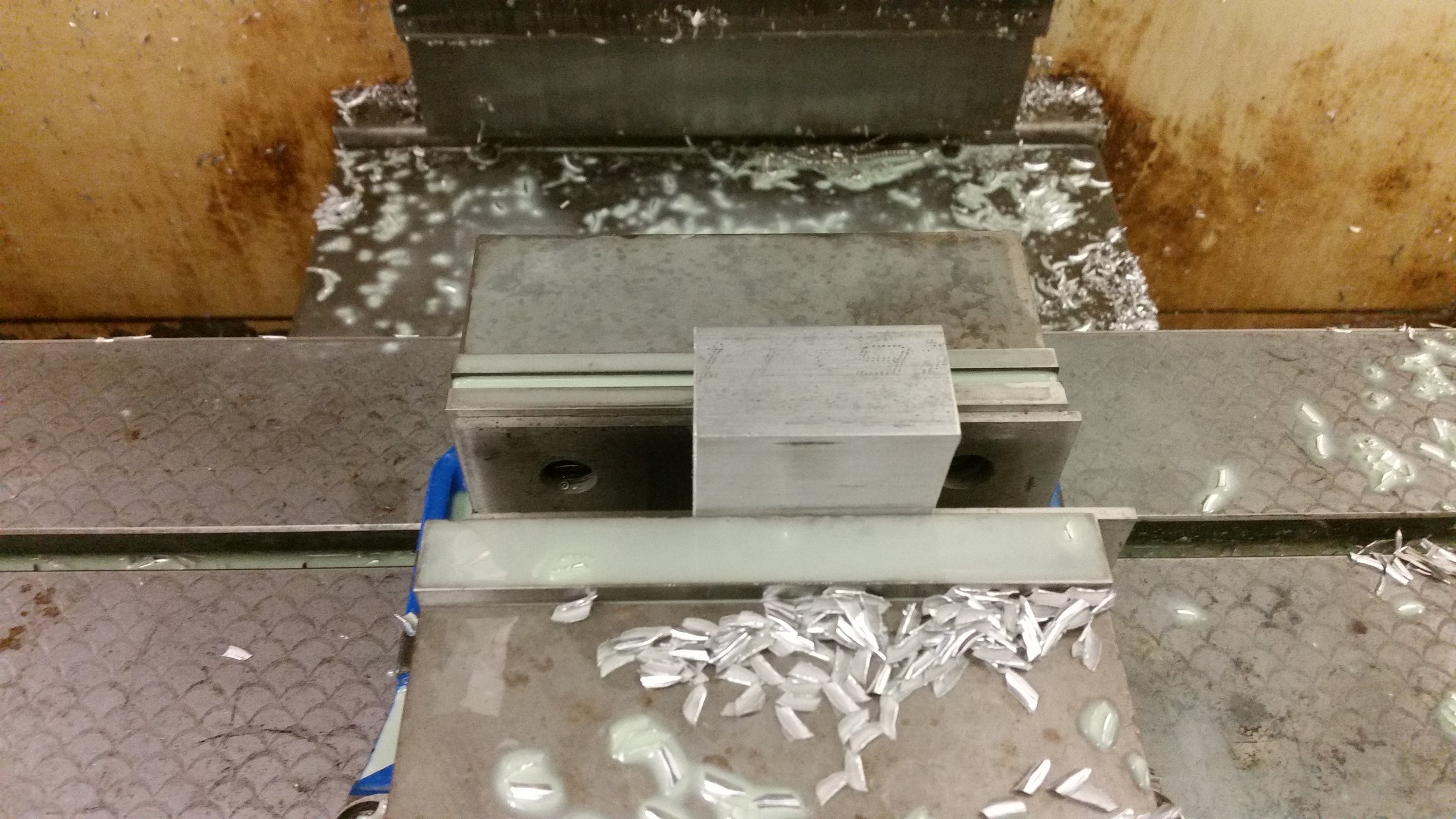

Steel rails, installed after painting, help ensure that the canister is able to move smoothly when actuated. Although these are not strictly required for the device to work, I do find that they considerably improve reliability

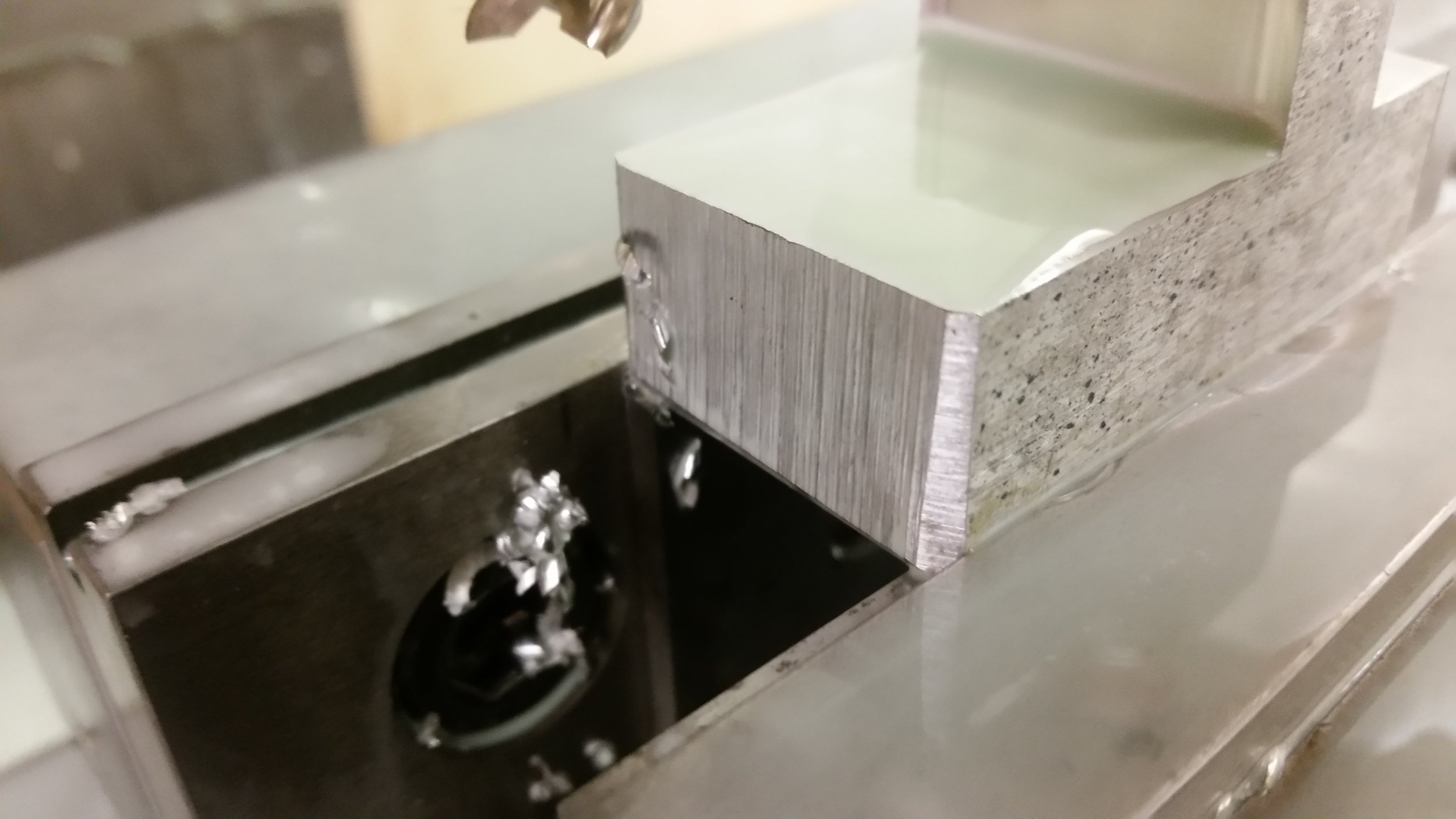

Depending on the exact build, it may be a good idea to bypass the ratcheting mechanism near the operation point of the thrower. This prevents it from ratcheting into a permanently “on” position. Filing the teeth of a short length of the plunger arm seems to accomplish this nicely.